The Earth Observation Characterisation Facility at Imperial College, overseen by the Space and Atmospheric Physics Group, is a resource for the development of instrumentation across a broad range of research applications. This 83m2 facility has been recently commissioned and was opened by UK Government Chief Scientific Advisor Sir Robert May in 1998. While it supports a full range of active characterisation projects for Blackett Laboratory physicists, it can also work with non-College partners in a range of technical tasks. These can be organised with the EOCF either as a dedicated facility accessible to external users, or contract work can be undertaken by Blackett Laboratory personnel using the EOCF facilities.

The Earth Observation Characterisation Facility at Imperial College, overseen by the Space and Atmospheric Physics Group, is a resource for the development of instrumentation across a broad range of research applications. This 83m2 facility has been recently commissioned and was opened by UK Government Chief Scientific Advisor Sir Robert May in 1998. While it supports a full range of active characterisation projects for Blackett Laboratory physicists, it can also work with non-College partners in a range of technical tasks. These can be organised with the EOCF either as a dedicated facility accessible to external users, or contract work can be undertaken by Blackett Laboratory personnel using the EOCF facilities.

The facility continues to evolve with a commitment to incorporating the most modern equipment and techniques. Users of the facility have access to expertise with the Department of Physics to assist with solutions in the areas of optics, electronics and mechanical design.

The EOCF would like to thank NASA and the crews of Apollo 7 and Apollo 17 for the images of Earth used in this web site.

Earth Observation Characterisation Facility

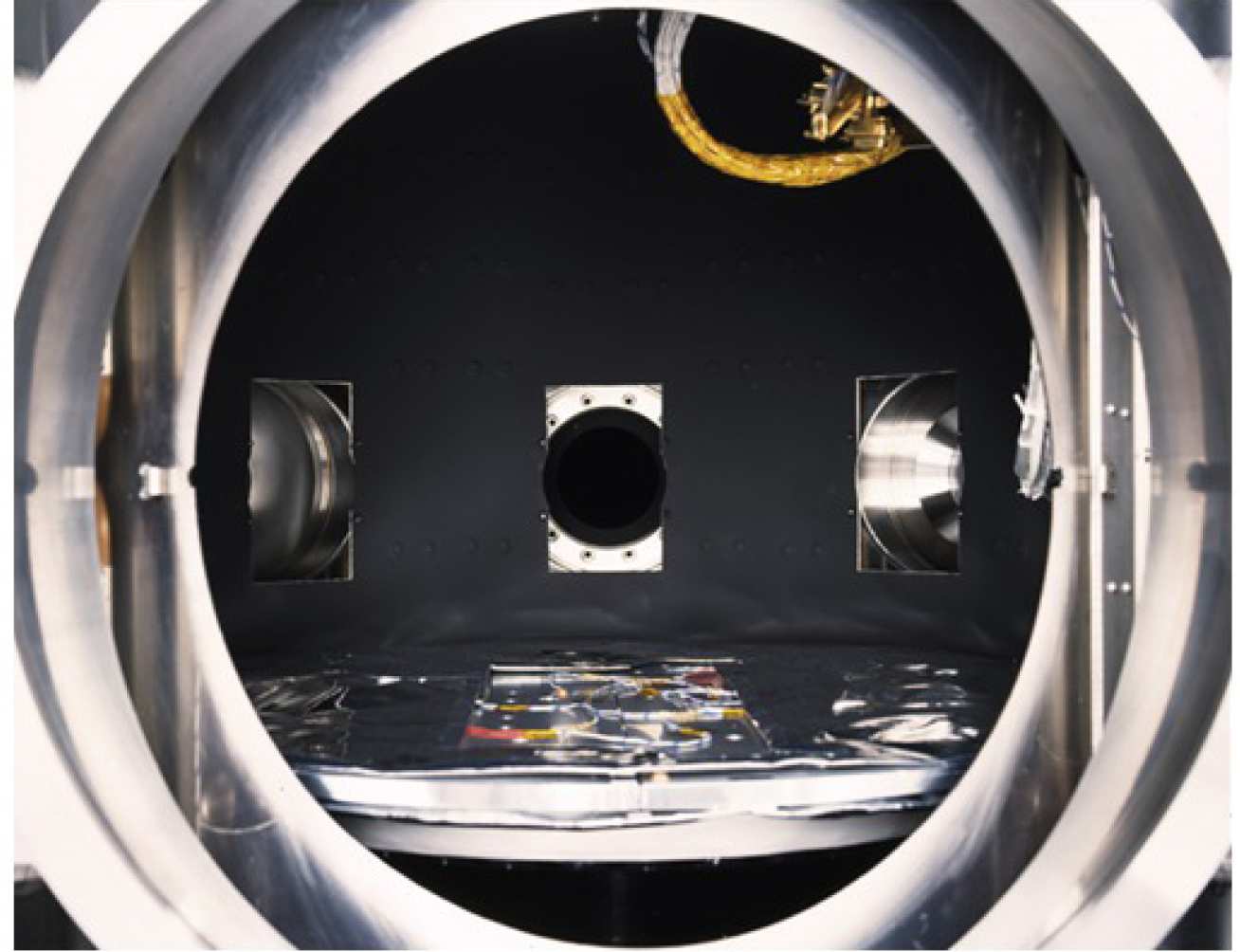

At the heart of the facility is the Vacuum Calibration Chamber (VCC). Designed from the ground up to support the calibration of space-based radiometers, this chamber offers the highest standards of precision and hydrocarbon-free cleanliness. The quality of the vacuum environment is assured through constant monitoring of trace gas species from 1 to 200 AMU using our quadrupole mass spectrometer.

At the heart of the facility is the Vacuum Calibration Chamber (VCC). Designed from the ground up to support the calibration of space-based radiometers, this chamber offers the highest standards of precision and hydrocarbon-free cleanliness. The quality of the vacuum environment is assured through constant monitoring of trace gas species from 1 to 200 AMU using our quadrupole mass spectrometer.

The chamber equipped with five 254mm conflat flanges in a radial configuration for accepting radiation sources. The usable inside diameter and height are 800mm and 922mm respectively. The tank pumping is completely oil-free. Roughing is done with a molecular drag pump and high-vac is achieved with cryogenic condensing array of 1500l/s capacity. When empty, the chamber can achieve a vacuum of better than 1.0e-8 torr. There are two main subsystems which extend the chamber’s capabilities: a two-axis articulating table and a thermal shroud.

Within the chamber is a table capable of 300mm of vertical travel and continuous 360 degree rotation, with motion resolution of 0.05mm and 0.5 degrees respectively. Load capacity is 30kg. The table can be used to point a spectrometric or radiometric device at any of the main source ports, or through a window which is aligned with the cleanroom optical worksurface. The table is computer controlled via GPIB.

Within the chamber is a table capable of 300mm of vertical travel and continuous 360 degree rotation, with motion resolution of 0.05mm and 0.5 degrees respectively. Load capacity is 30kg. The table can be used to point a spectrometric or radiometric device at any of the main source ports, or through a window which is aligned with the cleanroom optical worksurface. The table is computer controlled via GPIB.

The chamber also houses a cylindrical thermal shroud with a temperature range of -30oC to +60oC and heat removal capacity of about 100W at the lowest extreme. At room temperature, the heat removal capacity is in the kilowatt range. The inside of the shroud is coated with Chemglaze Z306 black paint, giving the shroud high thermal emissivity with low visible light scatter.

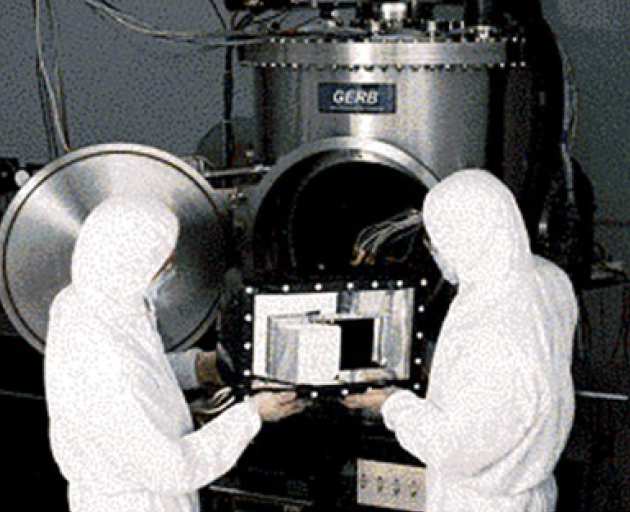

The EOCF has an access-controlled cleanroom with 28m2 of usable floor area and a volume of 60m3 maintained at class 1000 (class G). The cleanroom air is completely changed once per minute, making it safe for activities involving large amount of inert gas discharge (e.g. purging during spectral absorption measurements).

The EOCF has an access-controlled cleanroom with 28m2 of usable floor area and a volume of 60m3 maintained at class 1000 (class G). The cleanroom air is completely changed once per minute, making it safe for activities involving large amount of inert gas discharge (e.g. purging during spectral absorption measurements).

The room has 32 230VAC outlets available in the wall trunking. The room is humidity and temperature controlled with a heat removal capacity of 18kW continuous load.

The facility is kept continually stocked with all of the clothing and supplies required to operate in the clean room environment. Access and procedures are tightly controlled, ensuring both the security and cleanliness of any project.

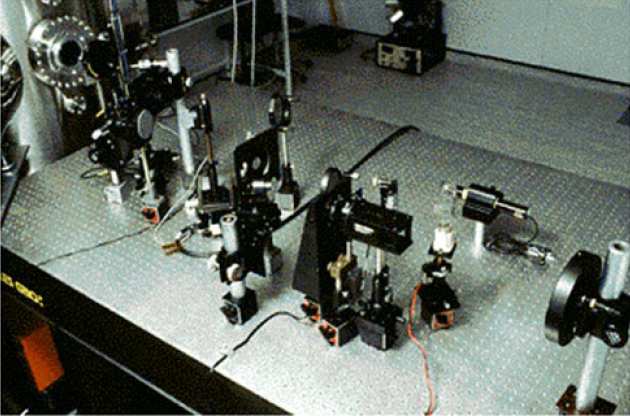

The facility owns four high-grade optical worksurfaces (one inside the cleanroom, one in the main lab and two in the satellite laboratory) and maintains a core inventory of bench optics. The table decks are Melles Griot 07OTQ501 models measuring 1.25m by 2.0m. Deck material is ferromagnetic stainless steel. Dynamic deflection coefficient, relative table motion and deflection under load specifications are all excellent. The support systems are self-levelling active vibration isolation systems with a load capacity of 2500kg. The table deck will be relevelled for an offset load of up to 250kg. Vertical and horizontal resonant frequencies are extremely low, being on the order of 1Hz.

The facility owns four high-grade optical worksurfaces (one inside the cleanroom, one in the main lab and two in the satellite laboratory) and maintains a core inventory of bench optics. The table decks are Melles Griot 07OTQ501 models measuring 1.25m by 2.0m. Deck material is ferromagnetic stainless steel. Dynamic deflection coefficient, relative table motion and deflection under load specifications are all excellent. The support systems are self-levelling active vibration isolation systems with a load capacity of 2500kg. The table deck will be relevelled for an offset load of up to 250kg. Vertical and horizontal resonant frequencies are extremely low, being on the order of 1Hz.

Users of the facility also benefit from access to physics department applied optics expertise.

EOCF users have access to the central Physics department workshop, encompassing a full array of machining, welding and fabrication capability. Standard electronic assembly facilities are present on site. Additionally, for high-cleanliness mechanical assembly there is a HEPA-filtered downflow bench. EOCF users have a clean and well-stocked tool chest to support their work, with additions being made constantly.