Supervisors: Dr Frederic Cegla, Mr Gabor Gubicza

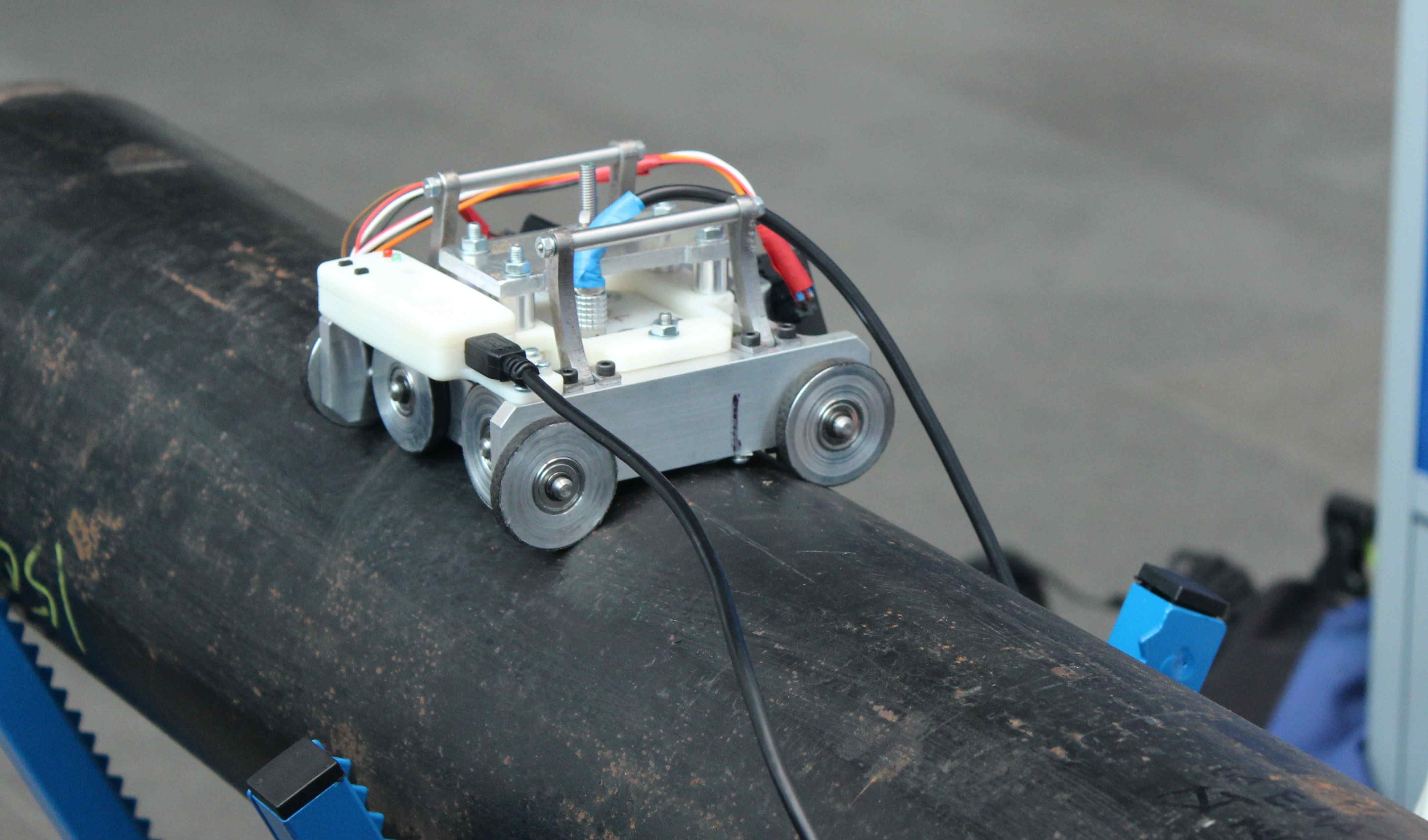

Pipes and plates are ubiquitous in structures around the world and can often develop defects which go unnoticed. The detection and characterisation of these defects is investigated by the Non-Destructive Evaluation group. The purpose of this project was to create a system for simultaneously recording ultrasonic and sensor position measurements, as well as processing this data to generate 3-D maps of material properties. As part of this project, two hardware elements have been developed. The first is primarily for scanning pipes and uses two encoders to measure the relative motion. The second element is for scanning flat specimens and uses two calibrated string potentiometers attached to a bar. The system is operated through a Matlab GUI which enables the acquisition and visualisation of ultrasonic data. It is possible to record ultrasonic echoes using piezoelectric transducers and EMATS, and then process these to evaluate thickness or speed of sound. The spatial maps of these properties can then be visualised within the GUI.