Food engineering

- Aeration of confectionery products via nozzle-based injection

- Extrusion of unleavened bread dough: experiments and simulations

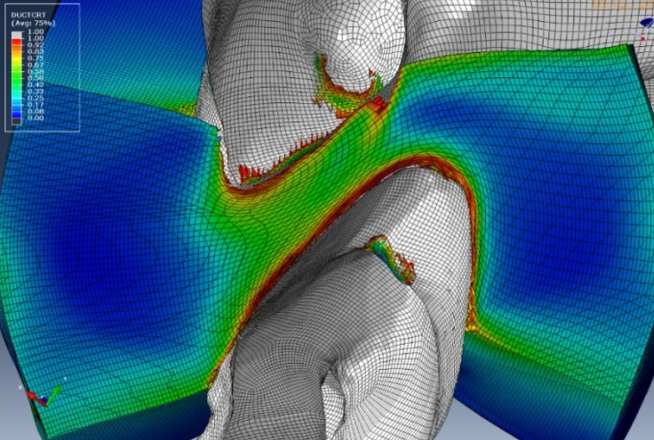

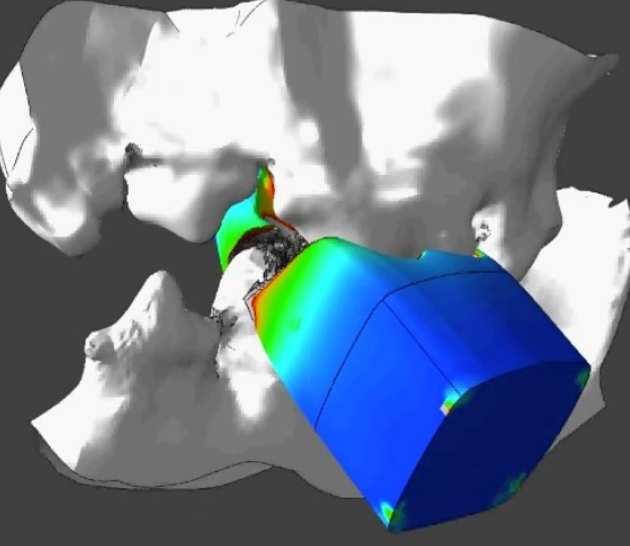

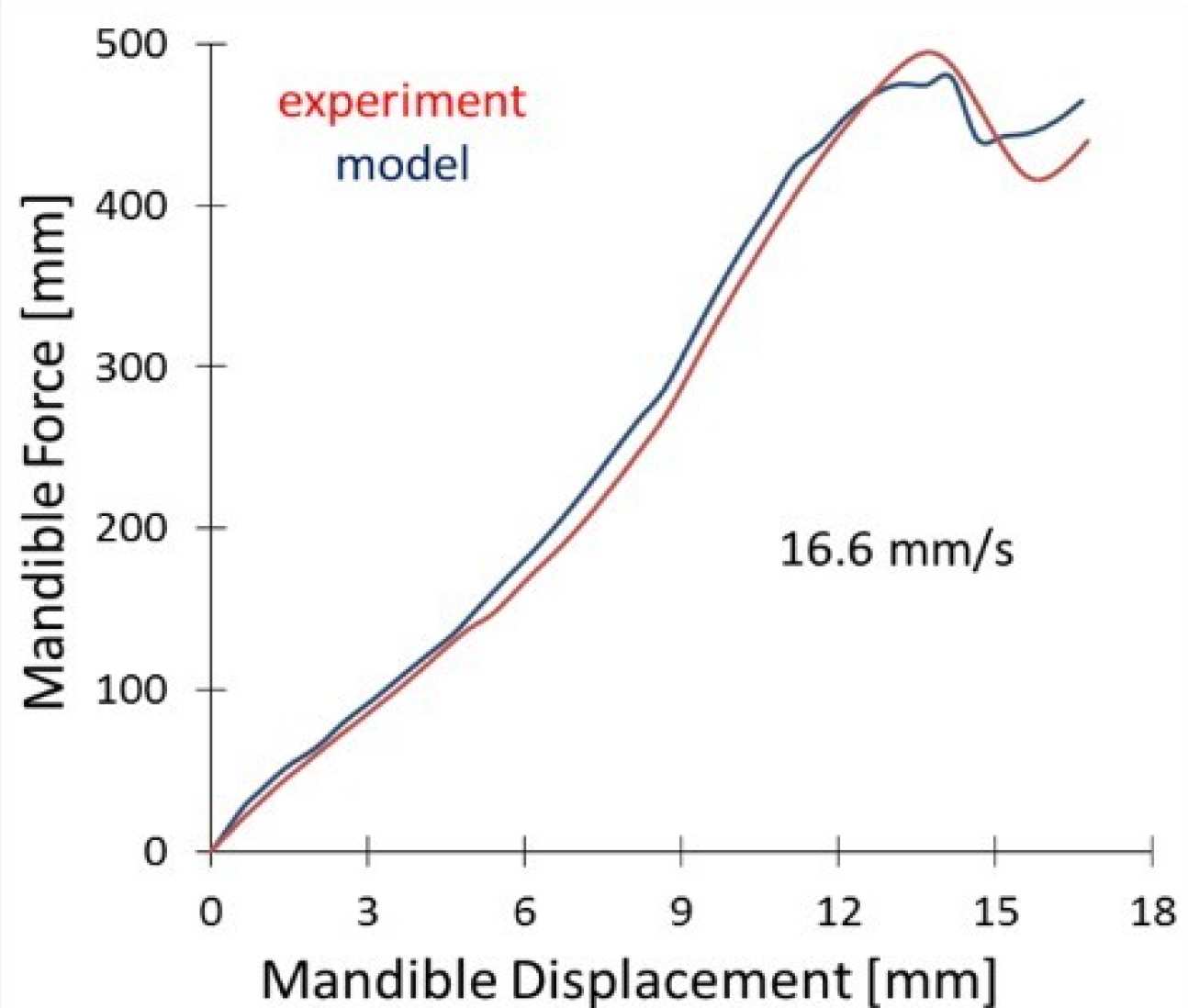

- Simulation of food oral processing

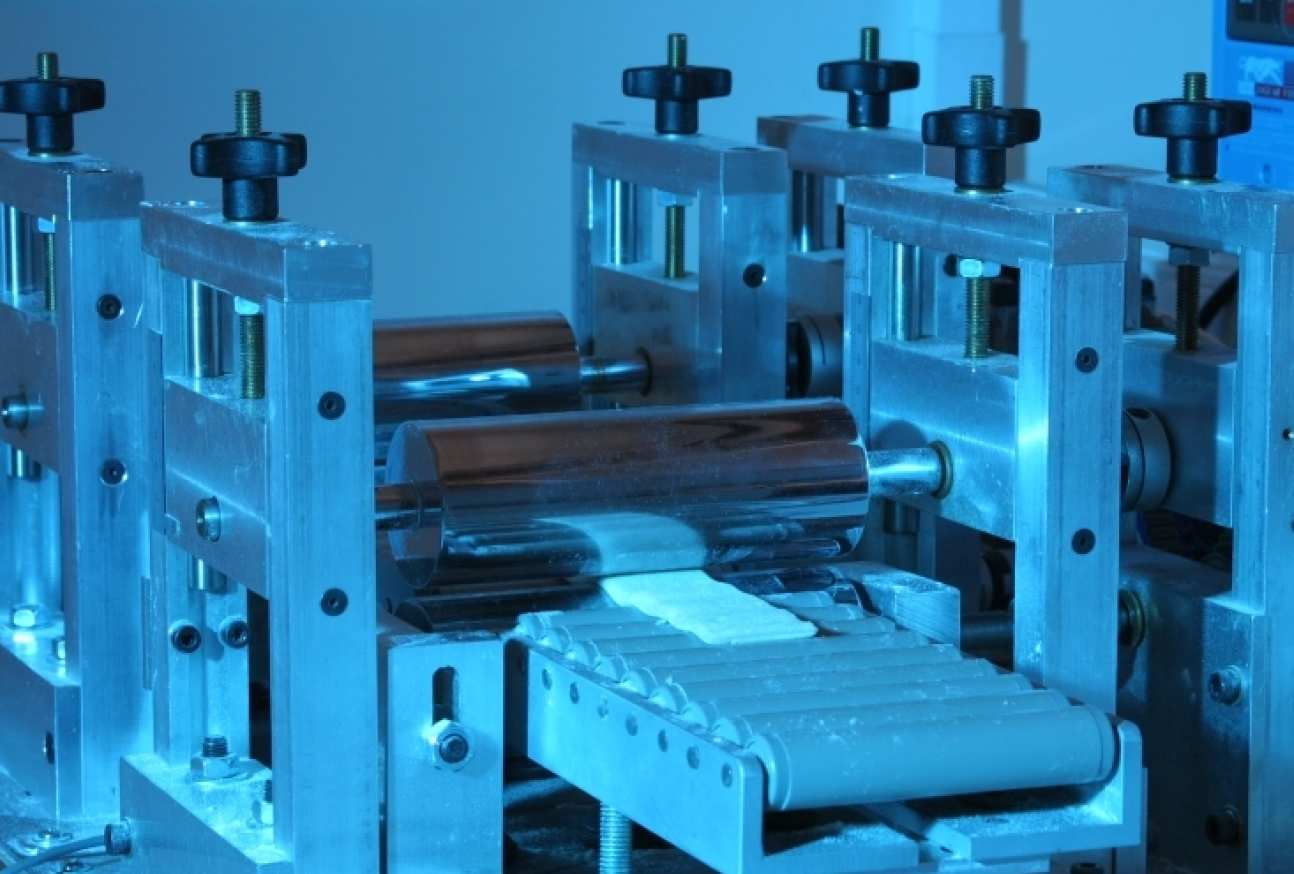

- Mechanical analysis and modelling the sheeting process of baked dough

- Mechanics of crushable food foams

Ross Winter, Maria Charalambides, Yannis Hardalupas

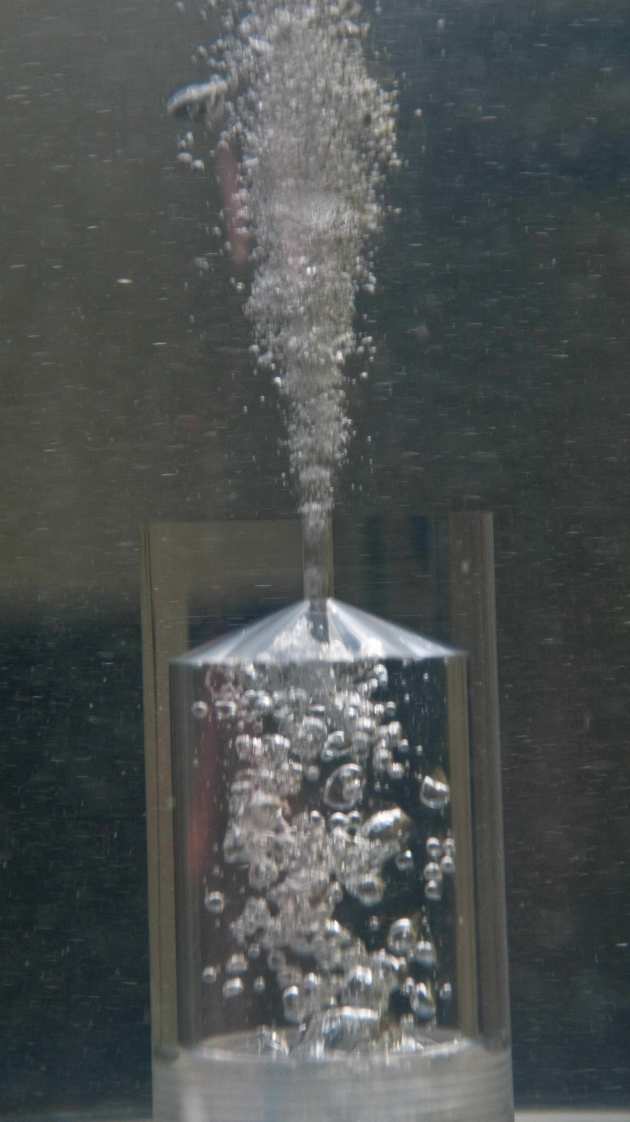

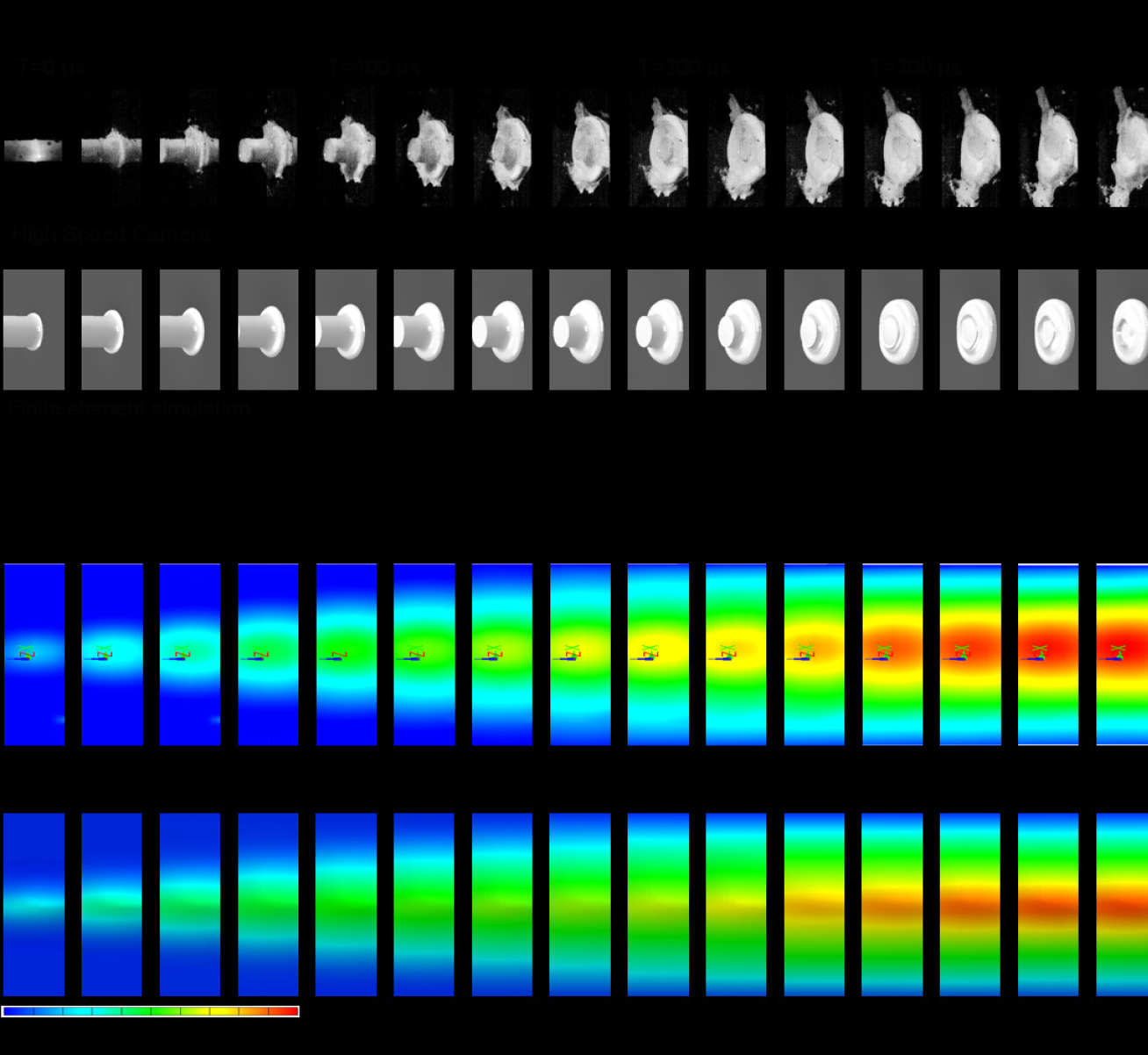

Bubble inclusions in confectionery products impart a desirable mouth-feel and unique sensory properties. This project studies the inclusion of bubbles through a novel nozzle-based injection method. The relationship between the operational/process parameters, the flow regime upstream of the nozzle and the downstream size distribution, is studied using a model air-water mixture.

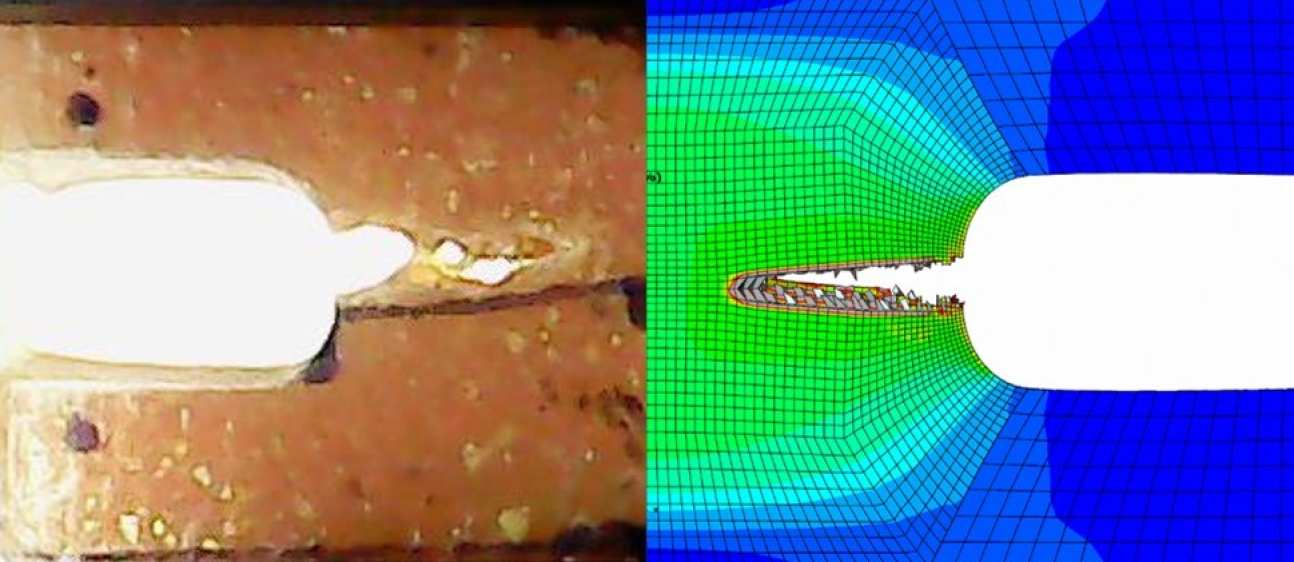

Fig 1- Bubbly and Churn Flow regimes upstream of the aeration nozzle

M.A. (Fendi) P. Mohammed, Leonard Wanigassoriya, Maria Charalambides

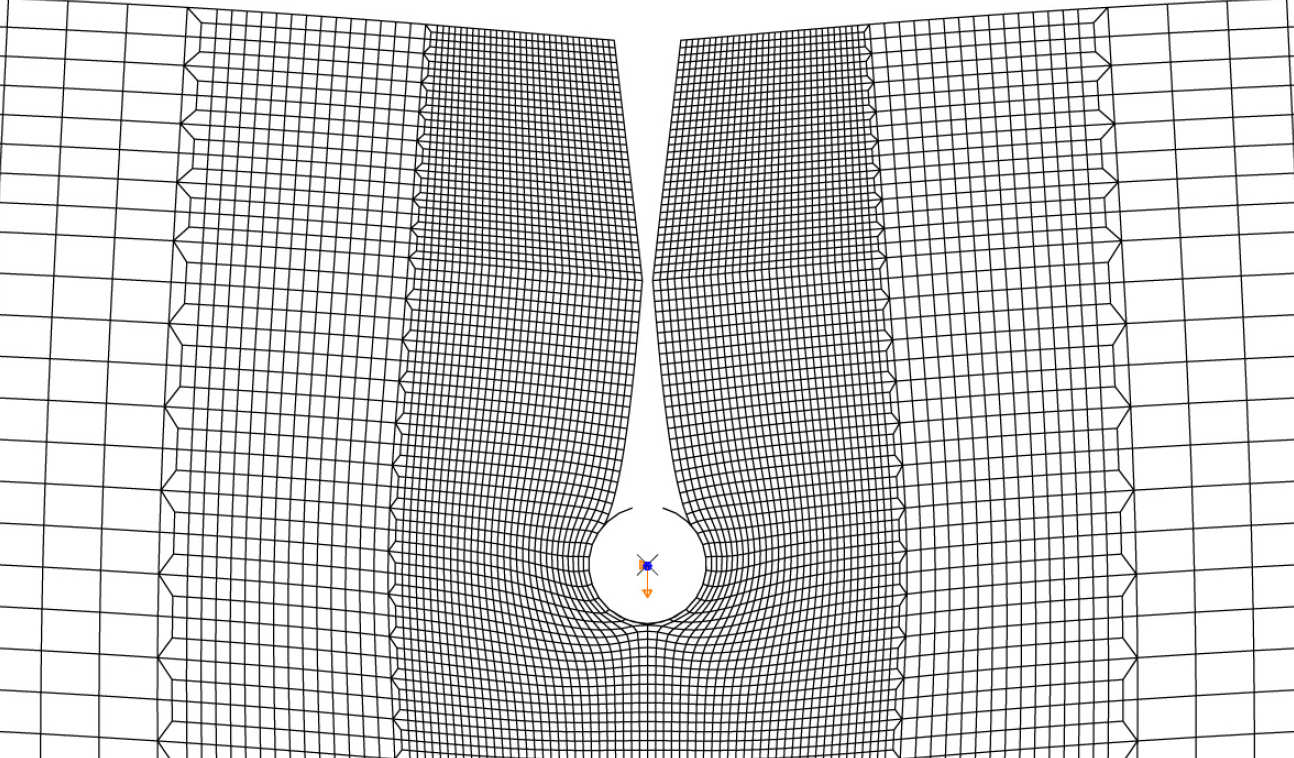

An experimental and numerical study on ram extrusion of bread dough was conducted in order to develop predictive models for the pressures involved, as well as the deformation of the extruded dough. Such studies are needed as high pressures can potentially lead tosignificant degassing, tearing, and shearing of the dough and hence poor bread quality; the latter limits the use of extrusion processes which would otherwise be a cost-effective forming process. A laboratory extrusion rig was designed, with dies of varying angles and exit radii. A simulation of extrusion was performed to predict the extrusion pressure as well as the extrudate swell, as a function of die geometry and extrusion rate. Static zones were observed both experimentally and numerically.

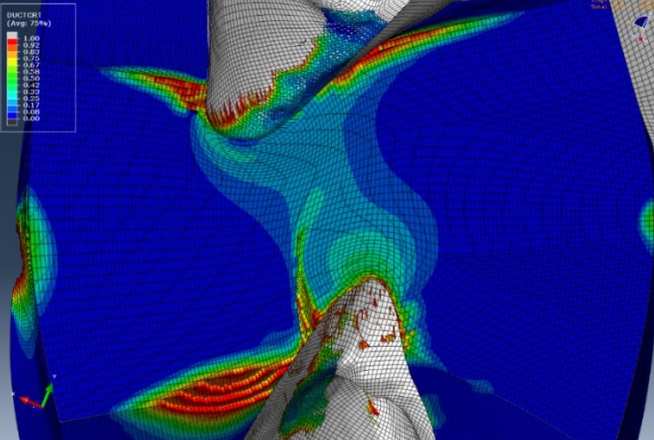

The stress-strain and toughness data are used in FE models to simulate food breakdown – the viscoplastic material model is implemented. Hard foods often display low ductility and toughness while they require high bite loads. Chewy foods undergo high deformations and display high fracture toughness.

Shirley Echendu, Wenfeng Xiao, Maria Charalambides

A predictive tool is developed for the analysis of the industrial rolling/sheeting process of dough through the characterisation of viscoelastic behaviour of selected dough samples, and simulation of sheeting process using a combination of experimental, analytical and computational (FEA) methods.

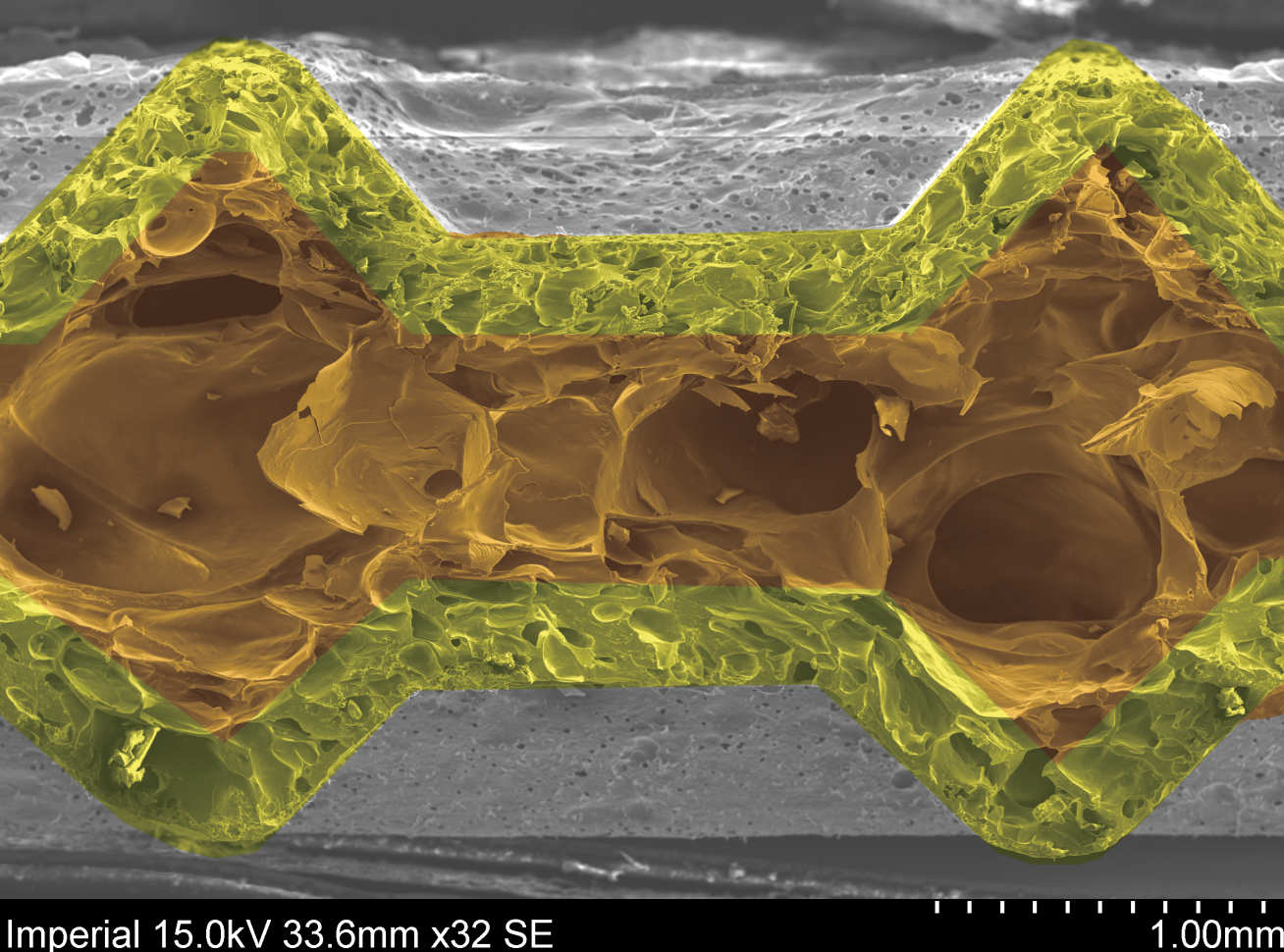

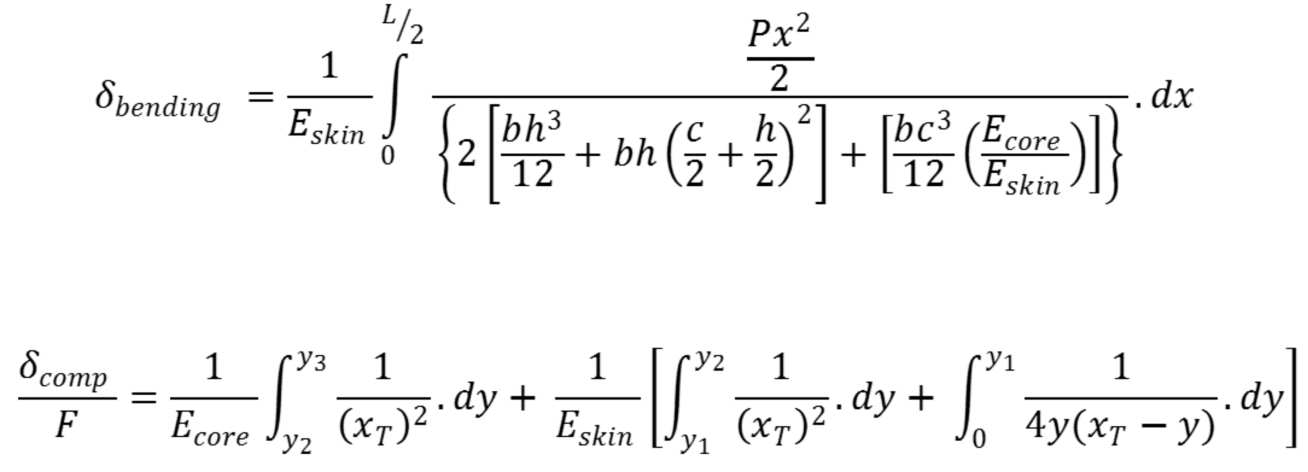

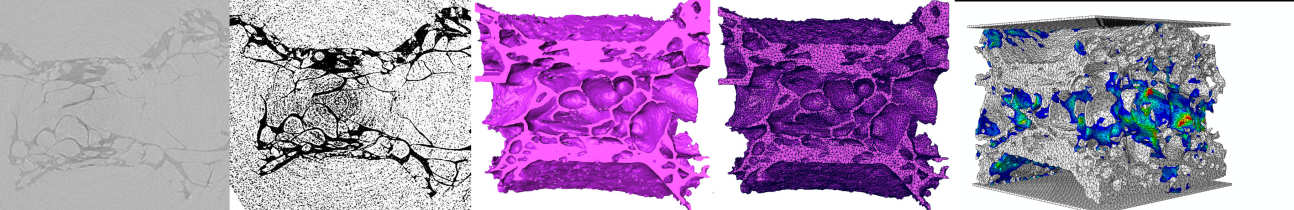

Maria Charalambides, J Gordon Williams, Idris Kevin Mohammed, Saba Butt

The aim of this research was to predict and simulate the material deformation of confectionery wafers using the finite element method so as to improve the manufacturing process and increase efficiency on the assembly line. This was done experimentally, analytically and numerically at both the macroscopic and microscopic level. The impact of this was research can also be used to correlate the mechanical response and sensory perception of confectionery products.

Fracture/ Cutting of Soft Solids

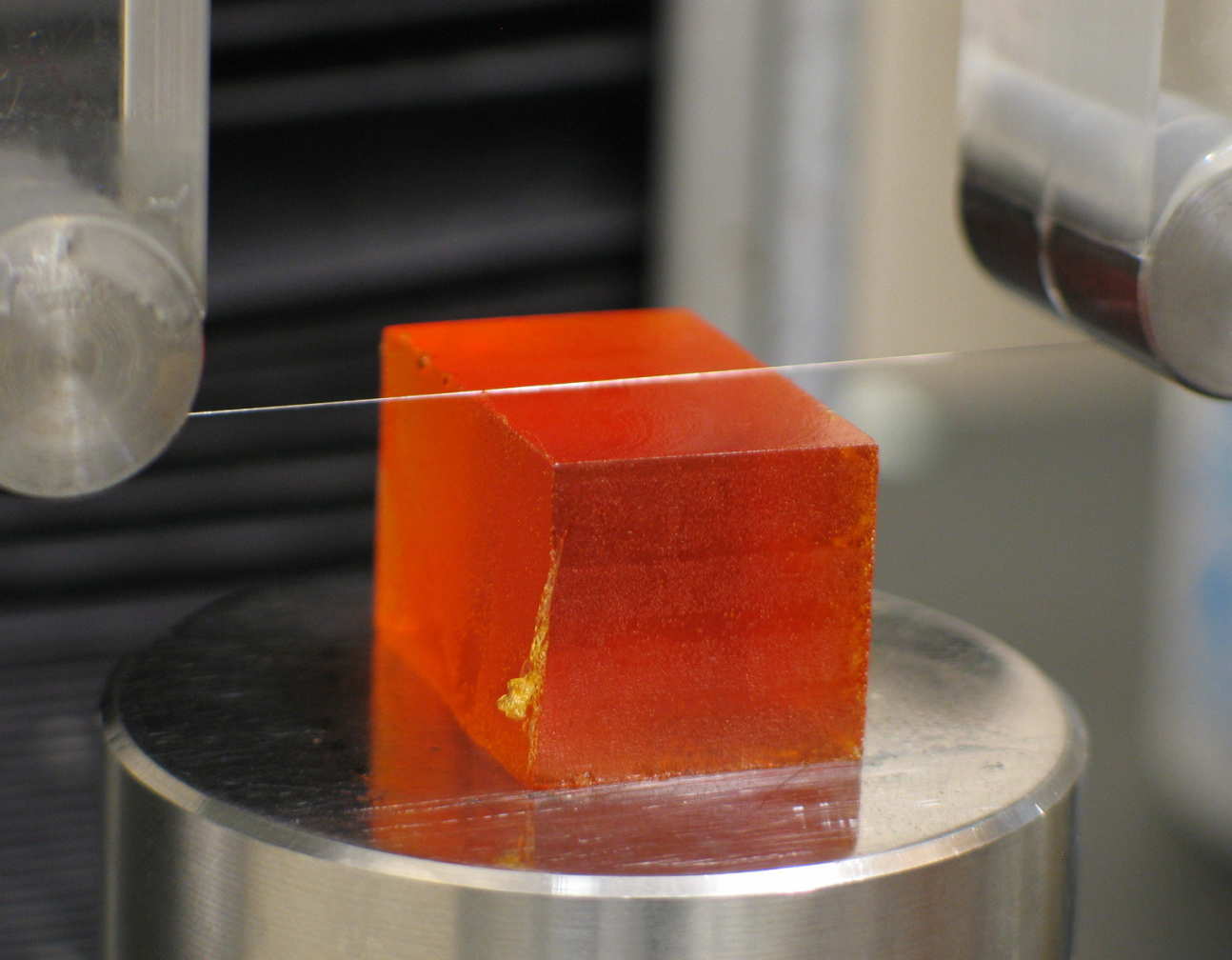

Christos Skamniotis, Yatish Patel, Maria Charalambides

Cutting is an important process in the food industry, whether this on the process line or a process that occurs during consumption. The group has performed a wide range of cutting tests suitable for soft foods, including wire cutting (of cheese or gels) or blade cutting (of cheese or petfoods). The aim is to extract the intrinsic fracture toughness from such cutting data. The results are validated through alternative fracture tests such the conventional Single Edge Notch Bend tests or the Essential Work of Fracture tests. Computational models are developed to simulate the cutting process in these soft solids using cohesive zone models.

C.G. Skamniotis, M.A. Kamaludin, M. Elliott, M.N. Charalambides

Determining fracture toughness for soft, highly dissipative, solids has been a challenge for several decades. Amongst the limited experimental options for such materials is the essential work of fracture (EWF) method. However, EWF data are known to be strongly influenced by specimen size and test speed. In contrast to time-consuming imaging techniques that have been suggested to address such issues, a simple and reproducible method is proposed. The method accounts for diffuse dissipation in the specimen while ensuring consistent strain rates by scaling both the sample size and testing speed with ligament length.We compare this new method to current practice for two polymers: a starch based food and a polyethylene (PE) tape. Our new method gives a size independent and more conservative fracture toughness. It provides key-data, essential in numerical models of the evolution of structure breakdown in soft solids as seen for example during oral processing of foods.

A novel essential work of fracture experimental methodology for highly dissipative materials

Particulate composites

Rouyu Zhang, Muhammed Iqbal Chatta, Hari Arora, Ed Tarleton, Joanna Li-Mayer and Maria Charalambides

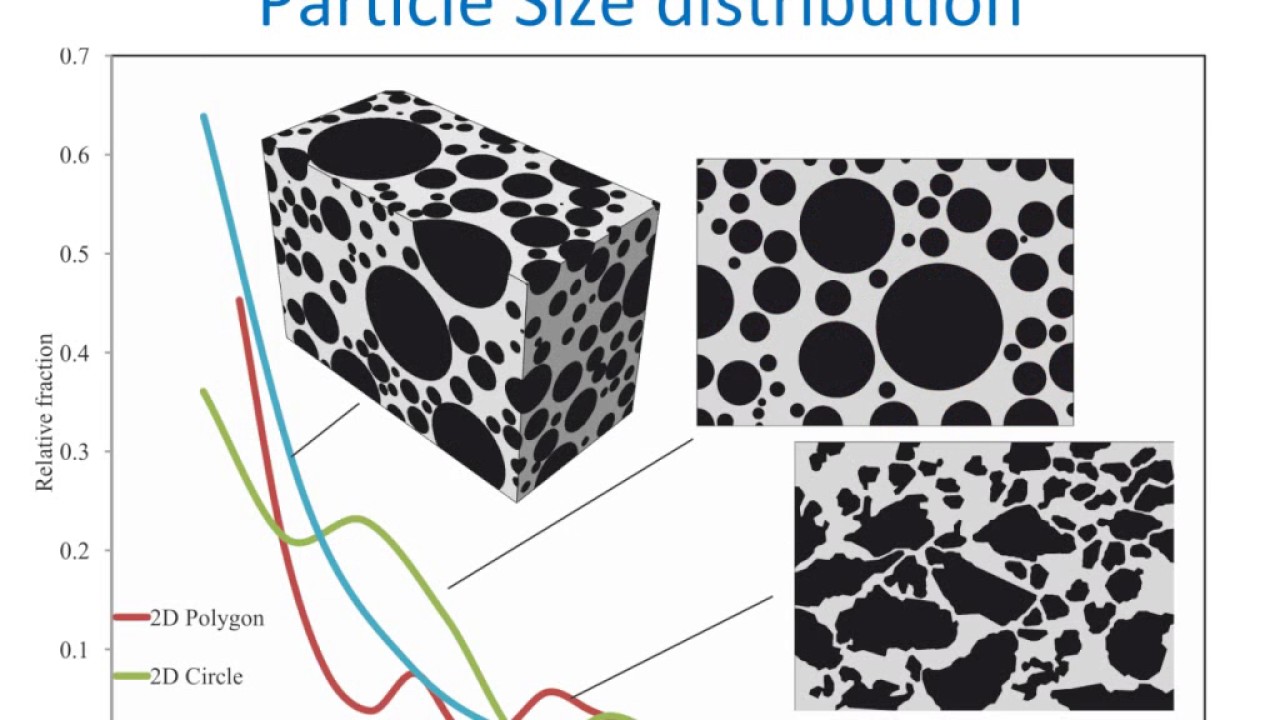

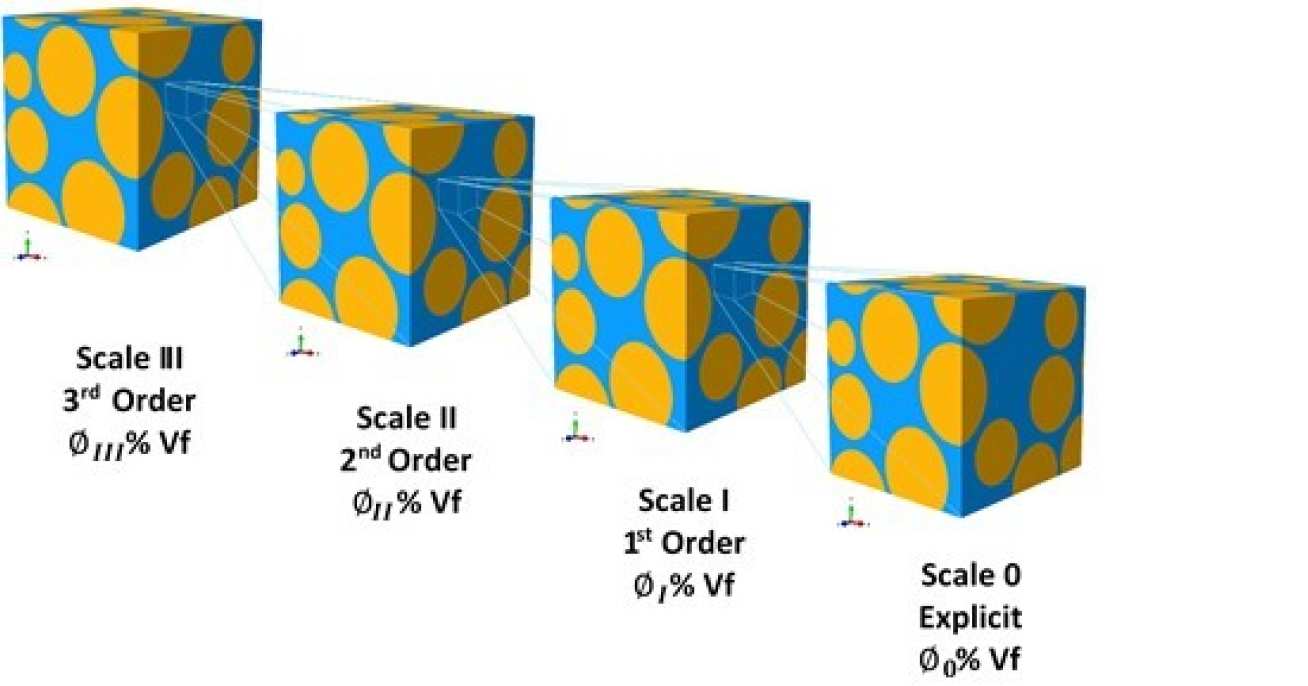

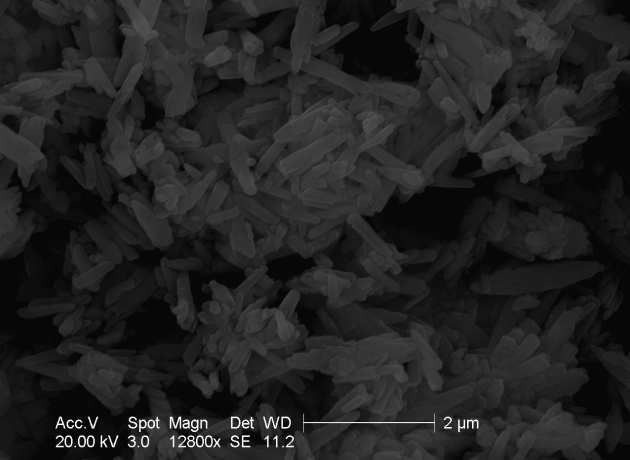

Particulate polymeric composites are materials which consist of rigid particles held in a polymer based matrix, PMMA/ATH and polymer bonded explosives are examples of such materials. The aim of this research is to predict the mechanical behaviour of the composites up to failure to aid the design of these materials. Using both analytical, micromechanical finite element models and experimental methods, this work also allows investigation of the relationship between the microstructure and mechanical properties.

Modelling the damage and deformation process in a plastic bonded explosive microstructure under tension using Finite Element method

Paints and coatings

Soratos Tantideeravit, Eric Hagan, Daniel Balint, Christina Young & Maria Charalambides

The group has a history of research into the mechanics of paints including micromechanical models for modern paints (acrylics) as well as predicting lifetime in painted works of art due to changes in environmental storage conditions in museums.

One objective of these studies is to model the effect of low amplitude cyclic stresses on multilayer paint systems found in works of art. Peel tests were performed to determine the cohesive zone properties of the paint interface. A finite element model of a coating on a primed canvas substrate was subjected to combined cyclic and static mechanical loadings typically experienced by fine art paintings. Interface separation was controlled by an irreversible cohesive zone model that includes damage accumulation due to cyclic loading. Fatigue crack initiation times in years were predicted for various conditions including ordinary and extreme histories that paintings may experience in museum and conservation settings. The work is about to be extended in a new collaborative study with the University of Glasgow (Christina Young) based on understanding and predicting crack formation in painted wooden cultural heritage.

Prediction of Delamination in Multilayer Artist Paints under Low Amplitude Fatigue Loading

Adhesives

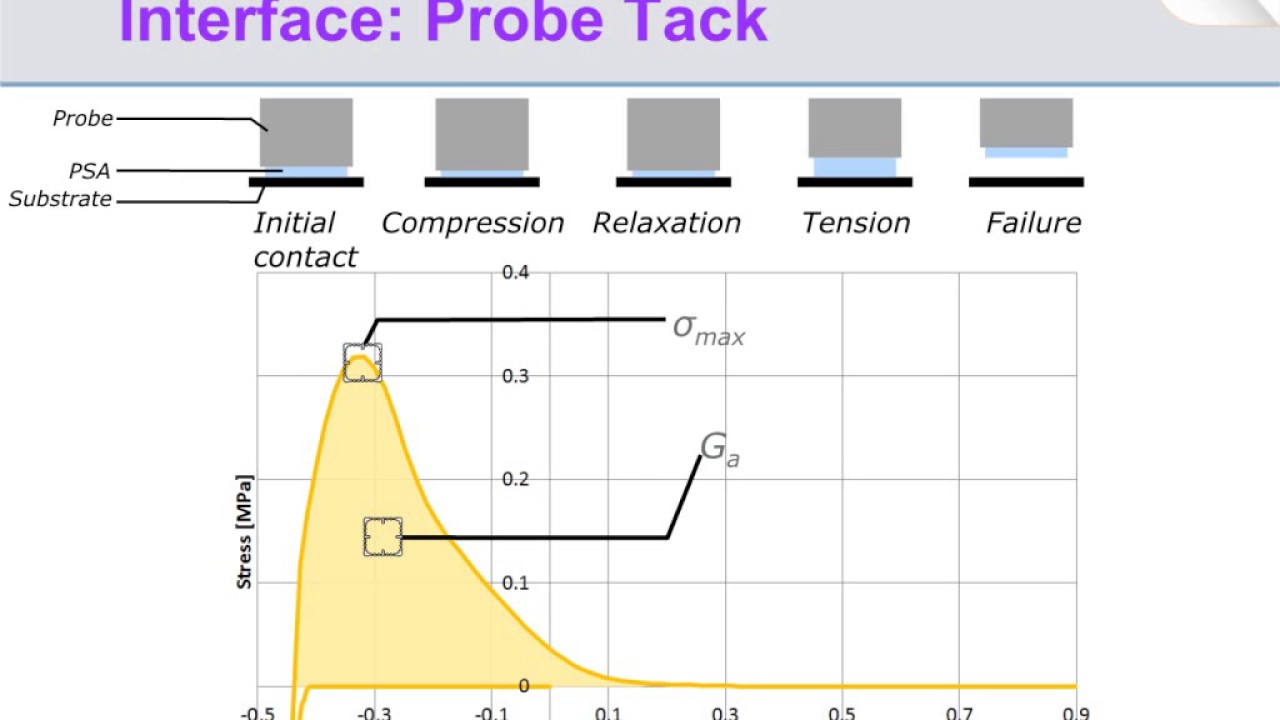

Maria Charalambides, Anthony Kinloch, Idris Kevin Mohammed

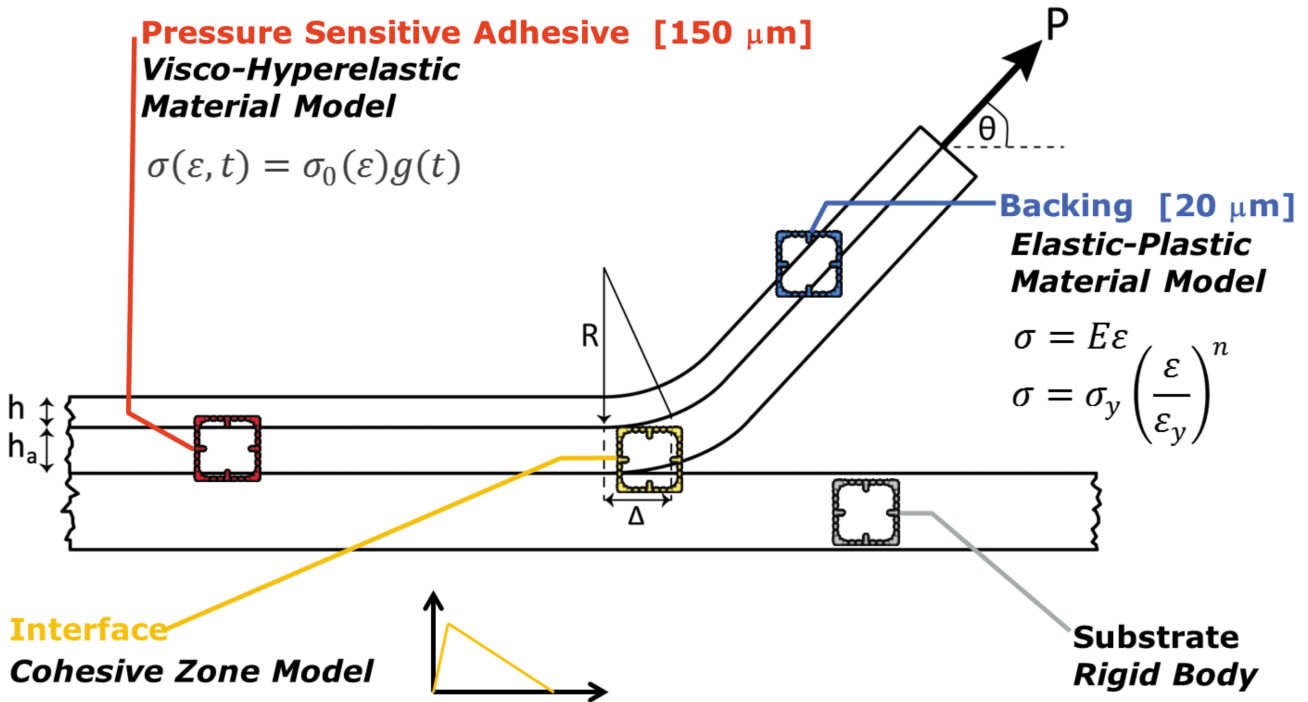

The aim of this research was to design and develop a drug loaded patch for the treatment of nail fungal infections. It included determining the optimal backing membrane/pressure sensitive adhesive (PSA) combination with good mechanical and adhesive properties for application to the nail plate. To mimic the removal of a patch from a nail, fixed arm peel experiments were performed at different angles, speeds and substrates and subsequently modelled using the finite element method.

Modelling the Interfacial Peeling of Pressure-Sensitive Adhesives

Material modelling

Inherent in all the studies of the group is to determine the correct constitutive law for the soft polymeric material, whether this is a matrix in a particulate composite such as paints or a consumer product such as food (the team has studied several foods such as cheese, doughs, gels, cheese). The group has therefore built up a considerable expertise in mechanical characterisation of such compliant materials as well as constitutive modelling. Experiments are complicated due to the soft nature of the material which excludes the use of standard methods derived for structural solid polymers. Rheological models are complex due to the highly non-linear, large strain, time dependent behaviour often also accompanied by damage/irreversible flow and/or poroelasticity.

Modelling and Experimental Characterisation of the Rate Dependent Fracture Properties of Gelatine Gels

Soft solids impact

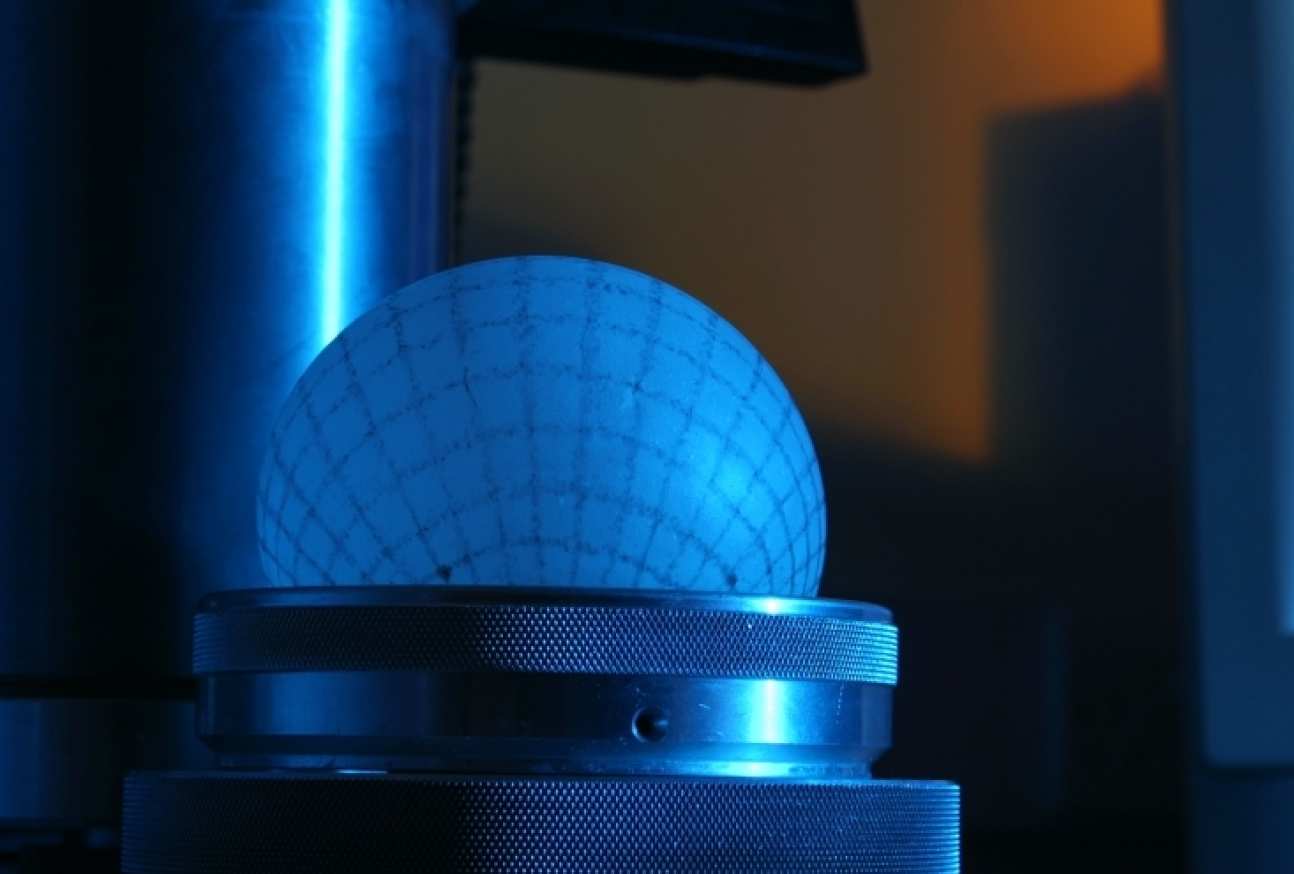

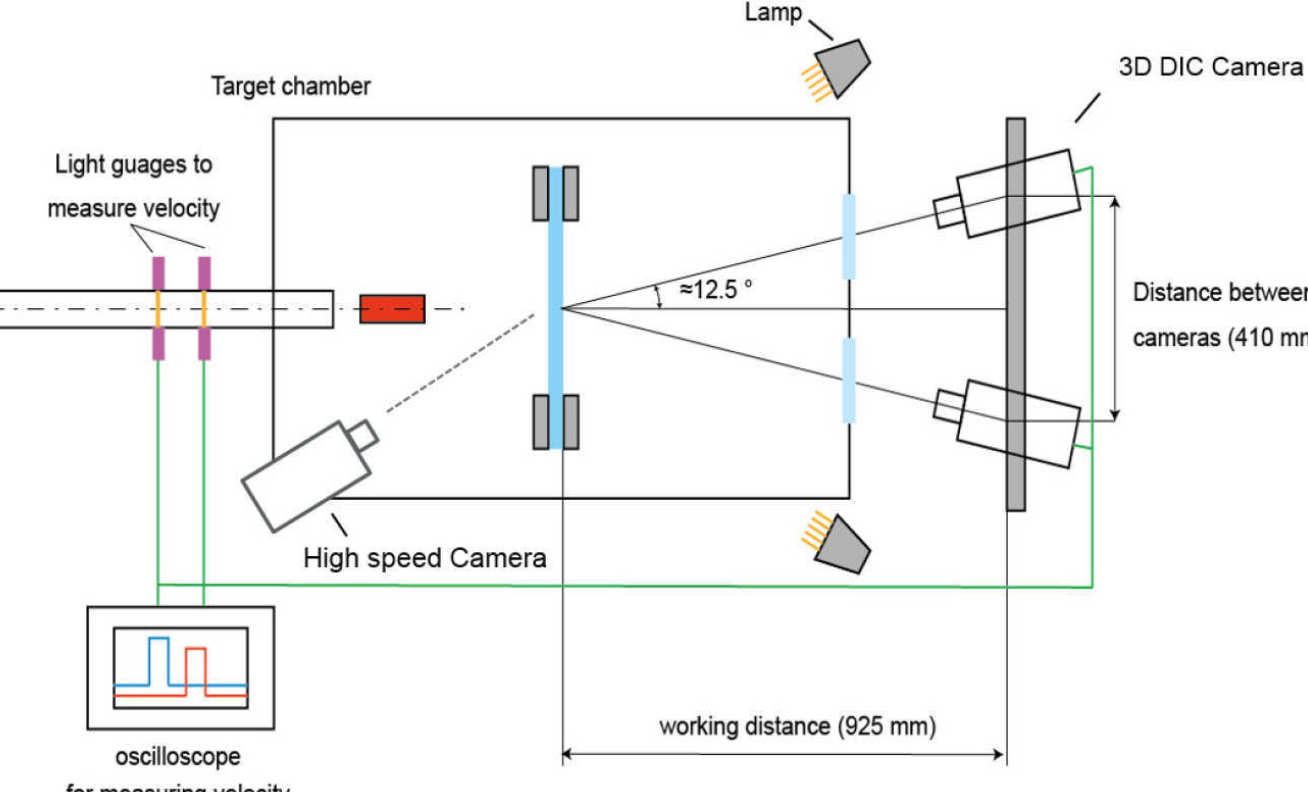

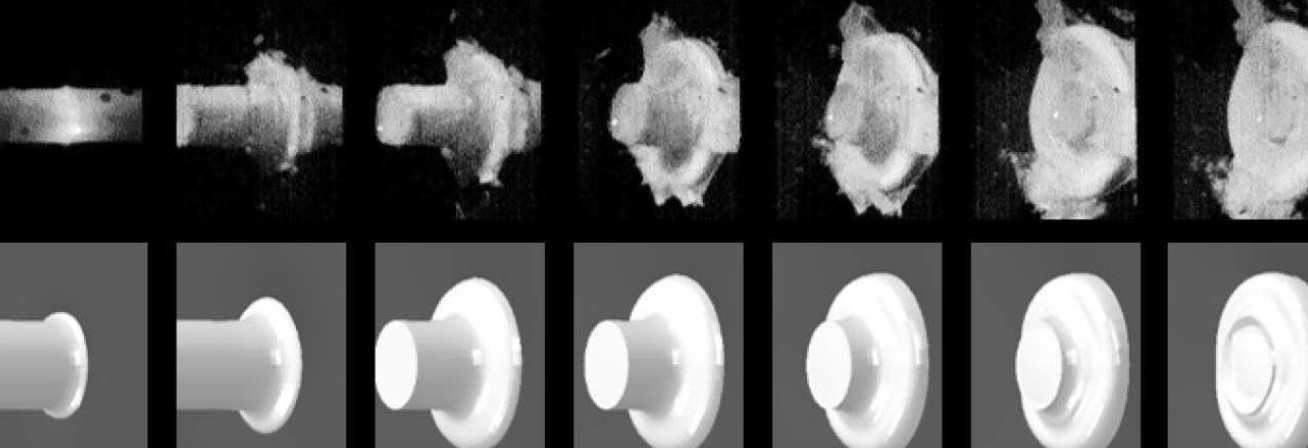

Jie Zhou, Iman Mohagheghian, Gordon Williams, John Dear, Maria Charalambides

Plastics Recycling

Investigators: Daniel Balint, Bamber Blackman, Maria Charalambides, Soraia Pimenta, Ambrose Taylor. PDRA: Manu Charles Mulakkal

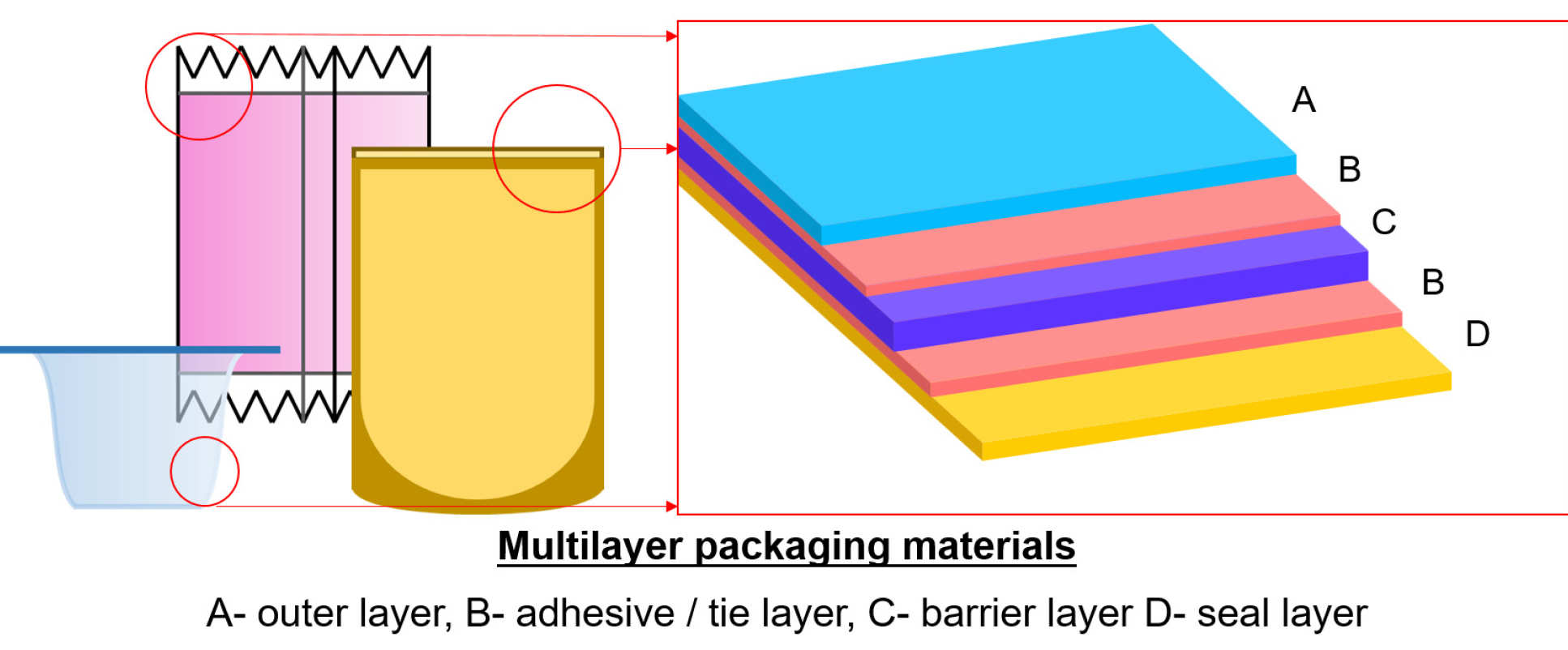

The group has a strong track record of renowned research into complex multiphasic materials and their microstructural characterisation, and adhesion. The expertise in these fields are now applied to help solve one of the pressing societal challenges that we face today - Plastic pollution. Multilayer packaging (MLP) films are utilised predominantly in food industry to extend the shelf life of food articles and they combine the merits of different functional materials in a single laminate form, thus performing a myriad of functions such as mechanical support, gaseous barrier, light barrier, sealability and printability for communication and brand identity. Currently, these packaging materials are landfilled or incinerated after their use as there are many inherent challenges that needs to be addressed to enable their recycling. The group’s research activities in this space includes developing material models to predict the mechanical properties of recycled MLP from combined melt processing. These material models can offer a virtual testing platform on which optimisation of recycled materials and their mechanical properties can be efficiently performed, greatly reducing the need for alternative trial-and-error approaches. Additionally, tapping into the group’s extensive experience on adhesion, new recycle friendly multilayer packaging designs are also being investigated to mitigate the challenges limiting the recyclability of MLP while preserving the value of recycled materials from MLP.

Contact us

Professor Maria N. Charalambides

Head of Soft Solids

T: +44 (0)20 7594 7246

E: m.charalambides@imperial.ac.uk

516 City and Guilds Building,

South Kensington Campus.

Sponsors

Our sponsors include EPSRC, BBSRC, General Mills, ICI, Nestle and Royal Commission for the Exhibition of 1851.