Project title: The Study of Fracture Mechanics in Mannesmann Piercing Process

Supervisors: Dr Jun Jiang, Xianyan Zhou

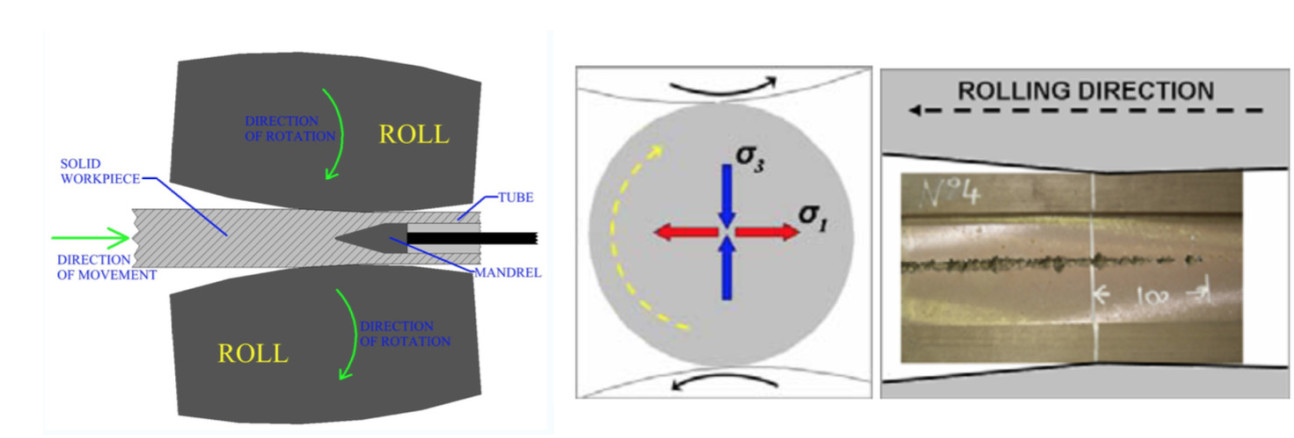

Mannesmann piercing process is one of the most common industrial operations to manufacture seamless pipes. Thanks to the Mannesmann effect, which refers to an axial cavity formed in the center of the material at the early stage of the process, seamless pipes are widely utilised in the oil and gas industries due to its high reliability and its structural rigidity. Numerous analytical and experimental studies on the piercing process have been performed in order to design and optimise the working parameters of the process and obtain higher quality of products. However, the scientific knowledge of fracture mechanics in the Mannesmann piercing process, especially the Mannesmann effect, is still limited. In this project, a new damage model is applied to study the fracture initiation in the Mannesmann piercing process. Numerical simulation and physical modelling approaches are both involved in this project in order to investigate the validity of the new damage model.