Charlie’s PhD sees him develop and test Microscale Rocket Propulsion Systems

Background

“I completed my BEng in Aerospace Engineering at the University of the West of England before moving to Imperial for my MSc in Advanced Aeronautical Engineering and my PhD. I also worked for a year in industry in the design and systems engineering departments at Leonardo helicopters.”

Research

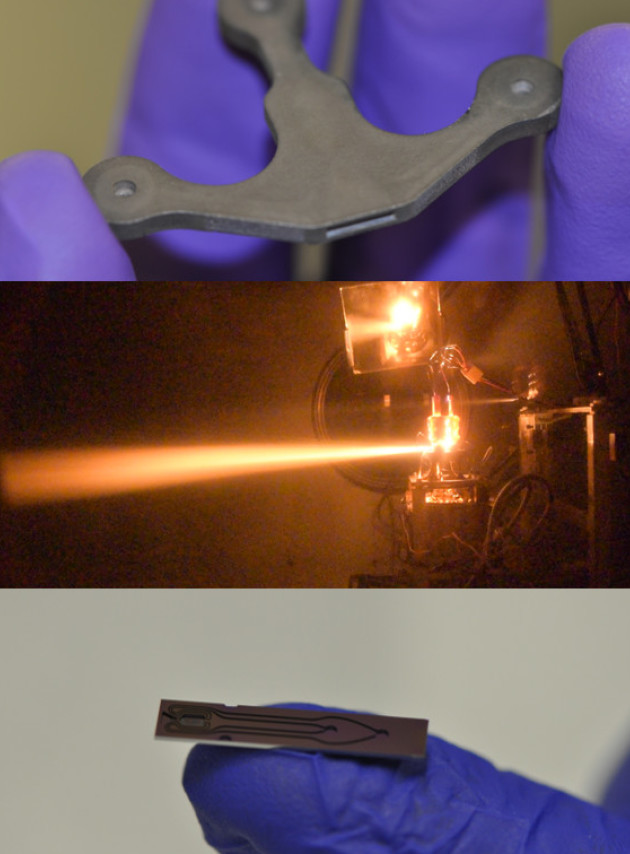

“My research focus is on the design, manufacture, and test of the ICE (Iridium Catalysed Electrolysis) thrusters. These are microscale rocket engine concepts that utilise MEMS-based manufacturing methods. These thrusters are designed for use on satellites where water is the primary-stored propellant, which is then electrolysed in-space into hydrogen and oxygen (which are very high-efficiency propellants for a rocket propulsion system). This offers extensive benefits from a performance and operational standpoint over current chemical propulsion systems, which rely on highly toxic and difficult to handle propellants such as hydrazine.”

The thing I have enjoyed most about the PhD has been taking the ICE thrusters from an idea on paper, through the manufacturing process and into testing."

“For me, I was always hugely interested in propulsion and space, so the PhD was a really great opportunity to do a deep dive into that field and develop some applicable knowledge. I also really liked the idea of conceptual research where you are free to explore new ideas and directions.”

Future Plans

“My current plan is to continue working on the ICE thruster project and continue the development towards a commercial product. We have been working closely with industrial partners throughout the PhD and have several exciting follow-on opportunities which are looking at commercialising the technology and hopefully getting the system into space one day!”

“The thing I have enjoyed most about the PhD has been taking the ICE thrusters from an idea on paper, through the manufacturing process and into testing. You learn a great deal when tackling all the problems involved in fabricating a novel concept like this and it is really satisfying when it all comes together and you can test the engine!”

PhD Challenges

“For me, the most challenging stage of the PhD has been the development work on the manufacturing process. We carried out a series of early test builds of the thrusters, and in some cases, we would see months of work literally break into pieces in front of our eyes. However, we managed to collect a lot of good data and learn important lessons along the way, and it was great to be there when we eventually got it right.”

“My main piece of advice when applying for a PhD is that you should make sure that the project is something that you are genuinely interested in and passionate about. It's a big commitment of time and it can be demotivating and challenging at times, but it makes it a lot easier if it is a subject which you have a passion for.”

Images: Top - ICE-200 (1N thruster for Small-Mid Sized Satellites); Middle - ICE-200 Hot Fire Test; Bottom - ICE-Cube (5mN thruster for CubeSats)