Composite Manufacture Facilities

- Ply Cutter

- Autoclave

- Diaphragm and thermoforming

- Press

- Liquid Composite Moulding

- Microbraiding

- Filament winding

- Composite 3D Printing

- Composite Repair

- Waterjet Cutter

- Composite Machining

- Furnace

Our conveyor belt cutter permits automatic, precise cutting of all types of dry fabrics and prepreg tapes. The cutter can handle complex shapes with ease and helps to minimise scrap by optimised arrangement of parts to be cut. The machine’s flexibility permits new research opportunities such an introducing defined discontinuities in preforms to simulate discontinuous in press moulded preforms. Due to its precision this cutter can be used to produce composite parts with accurately positioned features (e.g. ply cuts, ply drops and holes) which can be required, for example, in the validation of finite element models.

Our conveyor belt cutter permits automatic, precise cutting of all types of dry fabrics and prepreg tapes. The cutter can handle complex shapes with ease and helps to minimise scrap by optimised arrangement of parts to be cut. The machine’s flexibility permits new research opportunities such an introducing defined discontinuities in preforms to simulate discontinuous in press moulded preforms. Due to its precision this cutter can be used to produce composite parts with accurately positioned features (e.g. ply cuts, ply drops and holes) which can be required, for example, in the validation of finite element models.

- Standard dxf files used as input.

- Max. cutting width: 1524 mm

- Max. cutting speed: 1000 mm/s

- Accuracy: ± 0.1 mm

- Repeatability: ± 0.1 mm

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

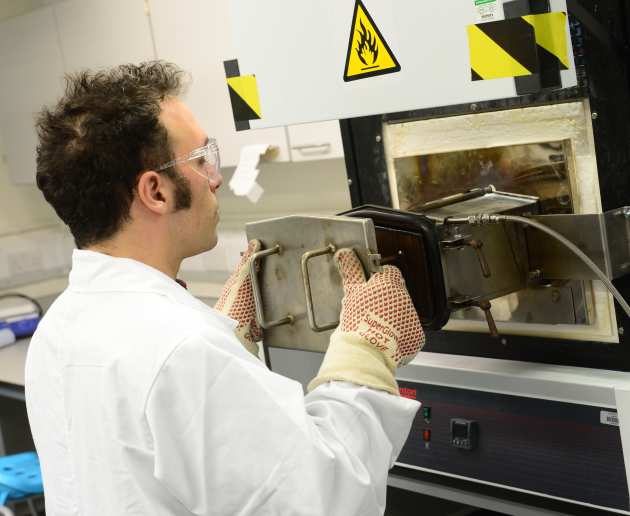

Our autoclave is able to process almost any thermoset and thermoplastic material. A maximum temperature of 450°C allows even most challenging thermoplastics such as PPS, PEEK and PEI to be processed. This equipment can be used to produce test specimens under precisely controlled conditions or complex parts such as aerospace grade stiffeners and stringers.

Our autoclave is able to process almost any thermoset and thermoplastic material. A maximum temperature of 450°C allows even most challenging thermoplastics such as PPS, PEEK and PEI to be processed. This equipment can be used to produce test specimens under precisely controlled conditions or complex parts such as aerospace grade stiffeners and stringers.

- Max. pressure: 400 psi (28bar)

- Max. temperature: 450°C

- Working table 800 mm x 2000 mm

- Vessel diameter: 1000mm

- 4 bag systems

- 12 thermocouples

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

Our heated vacuum press allows out-of-autoclave processing of thermoset materials. The flexible silicone tooling is used for one-sided diaphragm forming of prepregs around mould tools with curing at temperatures up to 250°C. In addition, we are able to thermoform thermoplastic materials into complex shapes.

Our heated vacuum press allows out-of-autoclave processing of thermoset materials. The flexible silicone tooling is used for one-sided diaphragm forming of prepregs around mould tools with curing at temperatures up to 250°C. In addition, we are able to thermoform thermoplastic materials into complex shapes.

- Max. temperature: 250°C

- Heating platen: 1450 mm x 1150 mm

- Tool stretch: 850%

- Max. tool height: 250 mm

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

With a maximum temperature of 400°C, our custom made laboratory press can not only be used to press mould and cure thermoset materials but also process high performance thermoplastics. A precise temperature and pressure control allows detailed research of the influence of manufacture parameters. Current research includes material compaction studies, investigation of varying bond-line thicknesses and press forming of multiple material panels for ballistic impact panels.

With a maximum temperature of 400°C, our custom made laboratory press can not only be used to press mould and cure thermoset materials but also process high performance thermoplastics. A precise temperature and pressure control allows detailed research of the influence of manufacture parameters. Current research includes material compaction studies, investigation of varying bond-line thicknesses and press forming of multiple material panels for ballistic impact panels.

- Platen size: 500 x 500 mm

- Pressure: 10-400 kN

- Tmax = 400°C

- Heating: 4 °C/min

- Cooling: 26°C/min

We are equipped with several means of performing liquid composite moulding processes. Our liquid infusion system uses the pressure pot principle where a pre-mixed resin systems is drawn into the machine under vacuum, actively degassed, then dispensed under pressure into the mould cavity. The temperature is controllable up to 150°C in multiple zones including the hose which is ideal for controlled RTM processes.

We are equipped with several means of performing liquid composite moulding processes. Our liquid infusion system uses the pressure pot principle where a pre-mixed resin systems is drawn into the machine under vacuum, actively degassed, then dispensed under pressure into the mould cavity. The temperature is controllable up to 150°C in multiple zones including the hose which is ideal for controlled RTM processes.

Alternatively, we are able to use low tech solutions for resin infusion under flexible tooling (RIFT). A heated platen is used to infuse previously degassed resin into a dry fibre reinforcement. The temperature can be controlled to reduce the resin viscosity or to cure the part after infusion.

Our Maypole-type braiding machine is used for the manufacture of microbraids. The machine is equipped with two working heads which allows the production capacity to be increased. By varying combinations of up to 16 carriers and 8 horn gears, a number of different braid patterns can be realised such a diamond 1/1 and regular 2/2 patterns. By varying the cogwheel ratio, the braid architecture such as the braid angle can be exactly controlled. This set-up also allows combinations of different yarns in a single braid and over-braiding of longitudinal yarns. Any custom combination of yarns can be prepared using our tension controlled rewinding unit.

Our Maypole-type braiding machine is used for the manufacture of microbraids. The machine is equipped with two working heads which allows the production capacity to be increased. By varying combinations of up to 16 carriers and 8 horn gears, a number of different braid patterns can be realised such a diamond 1/1 and regular 2/2 patterns. By varying the cogwheel ratio, the braid architecture such as the braid angle can be exactly controlled. This set-up also allows combinations of different yarns in a single braid and over-braiding of longitudinal yarns. Any custom combination of yarns can be prepared using our tension controlled rewinding unit.

- Max. pick-up speed: 30 m/h

- Use up to 16 carriers

- Use up to 8 horn gears

Using filament winding, it is possible to manufacture cylinders and closed end structures such as pressure vessels or tanks. Our robotised system also allows flat panels to be manufactured if desired. Accurately controlling the mandrel rotation, material supply rate, filament tension and robot movements ensures that the filament is placed in the desired orientation and position. This process can also be used in conjunction with the microbraider which enables processing of customised yarns.

Using filament winding, it is possible to manufacture cylinders and closed end structures such as pressure vessels or tanks. Our robotised system also allows flat panels to be manufactured if desired. Accurately controlling the mandrel rotation, material supply rate, filament tension and robot movements ensures that the filament is placed in the desired orientation and position. This process can also be used in conjunction with the microbraider which enables processing of customised yarns.

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

We can 3D print fibre reinforced composite materials using our desktop Markforged 3D printer. Combining a tough Nylon matrix with continuous carbon, glass and Kevlar fibres, or even a combination of these, in a single step makes this a real composites 3D printer. This printer allows us to optimise the fibre architecture of a printed part and customise the strength and stiffness as desired.

We can 3D print fibre reinforced composite materials using our desktop Markforged 3D printer. Combining a tough Nylon matrix with continuous carbon, glass and Kevlar fibres, or even a combination of these, in a single step makes this a real composites 3D printer. This printer allows us to optimise the fibre architecture of a printed part and customise the strength and stiffness as desired.

- Achievable Vf ~36%

- Repeatability 10 μm

- Max layer resolution: 200 μm

- Max print dimensions: 320 x 132 x 160 mm

We have specialised equipment to perform research on repairs of advanced composite structures. These repairs can be on flat and curved surfaces as well as on solid composite structures or sandwich panels. After precisely machining out individual layers of a damaged structure, we can then bond patches under controlled heat and vacuum pressure in an out-of-autoclave process to achieve high quality repairs.

We have specialised equipment to perform research on repairs of advanced composite structures. These repairs can be on flat and curved surfaces as well as on solid composite structures or sandwich panels. After precisely machining out individual layers of a damaged structure, we can then bond patches under controlled heat and vacuum pressure in an out-of-autoclave process to achieve high quality repairs.

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

Our Composites Suite is equipped with a waterjet cutter which allows test specimens and parts to be cut precisely to the desired shape. This reduces the risk of delamination which can be a problem for other cutting processes and ensures accurate, repeatable cutting even for complex shapes.

Our Composites Suite is equipped with a waterjet cutter which allows test specimens and parts to be cut precisely to the desired shape. This reduces the risk of delamination which can be a problem for other cutting processes and ensures accurate, repeatable cutting even for complex shapes.

- Max cutting size ~ 1.2m x 1.0m

- Traverse Range up to 10 m/min

- Linear Straightness Accuracy ±0.07 mm

- Repeatability ±0.060 mm

- Operating pressure 60,000 psi

- Input: Standard dxf files

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

For fabrication of multifunctional materials we have a furnace which is used to pyrolise materials under an inert atmosphere.

Technical Details:

- Lenton (ECF 12/45) furnace

- 42 litre capacity

- maximum temperature of 12000C

- inert (nitrogen) atmosphere.

Point of Contact: Dr Sang Nguyen (s.nguyen06@imperial.ac.uk)

Contact us

The Composites Centre

Imperial College London

South Kensington Campus

London

SW7 2AZ

United Kingdom

Email: ae.composites@imperial.ac.uk