Since 2019, the Department of Chemistry has proudly operated a state-of-the-art ISO6/7 Cleanroom at the Molecular Sciences Research Hub in White City. This advanced facility, spanning 150 m², supports a wide range of research and development activities in energy, materials science and molecular material design, enabling cutting-edge advancements in these fields.

Chemistry Cleanroom

Facility Highlights

Three Specialised Labs:

- Two Thin Film Semiconductor Processing Labs: Dedicated to the fabrication and optoelectronic measurement of devices such as solar cells, LEDs, transistors, wearable devices and photodiodes. This lab supports cutting-edge research in energy, materials science, and molecular material design.

- Microfluidic Device Fabrication Lab: Focused on creating lab-on-a-chip devices and conducting in vitro biological studies.

Sustainability and Efficiency: Awarded the Gold Award for the Laboratory Efficiency Assessment Framework (LEAF) in 2022, recognising its commitment to sustainable and energy-efficient operations.

MSRH Optoelectronic Device Fabrication and Characterisation Facility

This premier facility includes professional wet lab areas within the ISO7 cleanroom, featuring inert atmospheric gloveboxes and comprehensive optoelectronic device measurement suites. Key equipment includes:

- Thermal Evaporators: Two systems, including the KJ Lesker, for depositing small molecules on electronic device interfaces.

- Solar Cell Characterisation: Equipped with AAA/ABB solar simulators and external quantum efficiency measurement units to meet international standards.

- Custom Measurement Systems: Specialised setups for evaluating LEDs and transistors.

- Perovskite Technology Area: Features an N2-filled glovebox with balance, programmable hot plates and spin coaters.

Equipment within the lab

AAA and ABB Newport Solar Simulators:

Simulate sunlight to test and characterise solar cells under standard conditions, ensuring they meet international performance standards.

3x MBraun Glovebox:

Equipped with a programmable spin coater and hotplates, this glovebox is dedicated to handling organic and perovskite materials, which are sensitive to air and moisture.

PVE300 Bentham Photovoltaic EQE Measurement System:

Measures the external quantum efficiency of photovoltaic devices, helping to assess and optimise solar cell performance.

Programmable Hotplates and Spin Coaters:

Essential for the precise application and processing of thin films, crucial in the fabrication of devices like solar cells and Light-Emitting Diodes.

Home-Built LED Measurement System:

Custom-built for evaluating the performance of LEDs, including their brightness, efficiency and spectral properties.

DRP-STAT-I400S μStfat-i 400s Potentiostat/Galvanostat/Impedance Analyzer, Metrohm:

Analyses electrochemical properties, which are crucial for studying materials used in batteries, sensors and other electronic devices.

Home-Built Probe Station for Transistor Characterisation:

Evaluates the electrical properties of transistors, aiding in the development and testing of semiconductor devices.

MBraun and Kurt J Lesker Evaporator:

Located in a glovebox, these evaporators deposit small molecules onto electronic device interfaces, which are crucial for creating high-quality thin films.

Diener Femto Oxygen Plasma System and Ossila Ozone Asher:

Used for surface cleaning and modification, enhancing the adhesion and performance of thin films and other materials.

ZAA 2300 Zehntner-Automatic Film Applicator Coater and R-K Knife Bar Coaters:

Provide uniform coating of materials, which is important for creating consistent thin films and layers in device fabrication.

Four-Point Probe for Surface Resistivity Measurement, Ossila:

Measures the electrical resistivity of thin films and materials, making this important for assessing their conductive properties.

Alpha Step Tencor D500 Surface Profilometer:

Measures surface roughness and film thickness, providing detailed surface characterisation essential for device fabrication.

Chemical workstations (Class ISO5)

Ideal for all types of wet chemistry processes e.g., pharmaceuticals, environmental testing, food and beverage analysis and materials science. This ensures a controlled environment for sensitive chemical reactions.

Contact Angle Goniometer, Ossila:

Measures the contact angle of liquids on surfaces, providing insights into surface energy and wettability.

Cleanroom

Cleanroom dry lab with glovebox facilities for handling air sensitive organic materials and evaporations of different types of electrode materials

Cleanroom dry lab with Perovskite device fabrication glovebox

Cleanroom wet lab facilities for handling all wet chemistry for fabrications of devices such as OLED, diode, solar cells and transistor fabrications

Microfabrication lab

The Microfabrication lab is a dedicated area for rapid prototyping of Polydimethylsiloxane (PDMS) microfluidic devices by soft lithography, with lab-on-a-chip and organ-on-a-chip applications. Photolithographic patterning of silicon wafers is conducted in an ISO Class 5 cleanroom environment inside chemical workstations.

Equipment within the microfab lab

These tools collectively support the fabrication and development of microchips and microdevices, enabling precise control over material properties and device structures.

Equipment within the microfab lab

Chemical Workstations (Class ISO5):

These workstations are designed for wet chemistry processes essential in microchip fabrication, providing a controlled environment to handle sensitive chemical reactions and materials.

Diener Zepto Plasma System and Harrick Air Plasma System:

These plasma systems are used for surface modification and cleaning. Plasma treatment can enhance the adhesion properties of surfaces and remove organic contaminants.

Wet Etching Facilities (KOH/Aqua Regia):

Wet etching involves using chemical solutions to selectively remove material from substrates. KOH (potassium hydroxide) is commonly used for silicon etching, while aqua regia is used for etching metals.

Laminar Flow Bench:

Provides a clean, particle-free environment for dry substrate treatments, ensuring that substrates remain uncontaminated during processing.

Programmable Shakers and Ultrasonic Baths:

Shakers are used for mixing and agitating solutions, while ultrasonic baths are used for cleaning and removing contaminants from substrates and microdevices through high-frequency sound waves.

Optical Lithography (Photolithography):

A critical technique for patterning microstructures on substrates. It involves using light to transfer a geometric pattern from a photomask to a light-sensitive chemical photoresist on the substrate.

Programmable Spin Coater and Hotplates:

Spin coaters are used to apply uniform thin films to substrates, while hotplates are used for baking and curing these films, which is crucial in the fabrication of microdevices.

Rapid Prototyping of PDMS Microdevices:

Enables the quick and efficient creation of polydimethylsiloxane (PDMS) microdevices, which are commonly used in lab-on-a-chip applications and microfluidic studies.

Collimated UV Light Source:

Provides a uniform UV light beam for processes such as photolithography and curing of photoresists, ensuring precise and consistent exposure.

Microfabrication lab

Microfabrication Wet lab. Credit: Alex Ainscough; Joshua Edel

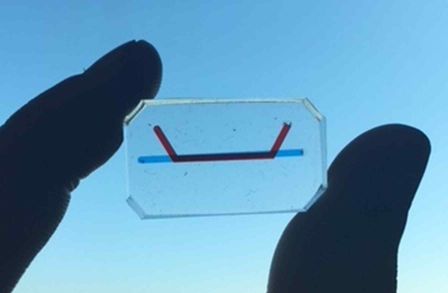

Pulmonary artery-on-a-chip, example of PDMS organ-on-a-chip devices. Credit: Alex Ainscough; Joshua Edel

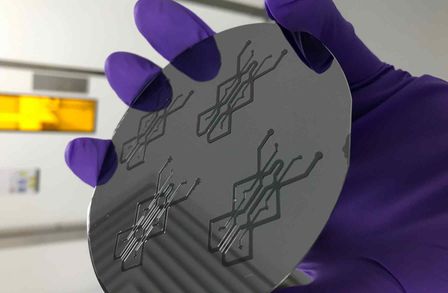

SU-8 Photolithographic patterning on silicon wafers. Credit: Manfredi San Germano; Oscar Ces

Registration and enquiries

These facilities are available to members of the university, and we also encourage enquiries from external customers, including academic, commercial and industrial users. We offer a wide range of services for custom devices, processed films, interfaces and electrode evaporations, allowing us to tailor our offerings to meet the specific research needs of both internal and external customers.

To know more about our facilities and accessing the cost of our facilities, equipment and our services, please visit here [for Imperial staff only]. To register as a cleanroom user, please complete the Cleanroom Access Request Form and for all other enquiries, please contact:

Dr. Pabitra Shakya Tuladhar (Cleanroom Manager)

e-mail: p.shakya@imperial.ac.uk

Tel: +44 (0) 207 594 5710

Work with us

We welcome requests from industry and academia to collaborate with us.