Supercapacitors provide exceptional power density, high dimensional stability, and very long cycle life, making them excellent candidates for new structural energy storage systems. They typically use high surface area carbon electrodes laminated with a separator (Shirshova et al., 2013 and Carlson and Asp, 2013). This architecture maps onto conventional composite laminate designs if suitable constituents are developed. However, there are several challenges. One is to provide a ‘structural electrode’, a conductive carbon-rich electrode with high electrochemical surface area and maximum mechanical performance, in particular stiffness and strength. Here, we use both intrinsically high strength nanoscale carbons (nanotubes), and combine high strength carbon fibres with nanostructured carbon matrices.

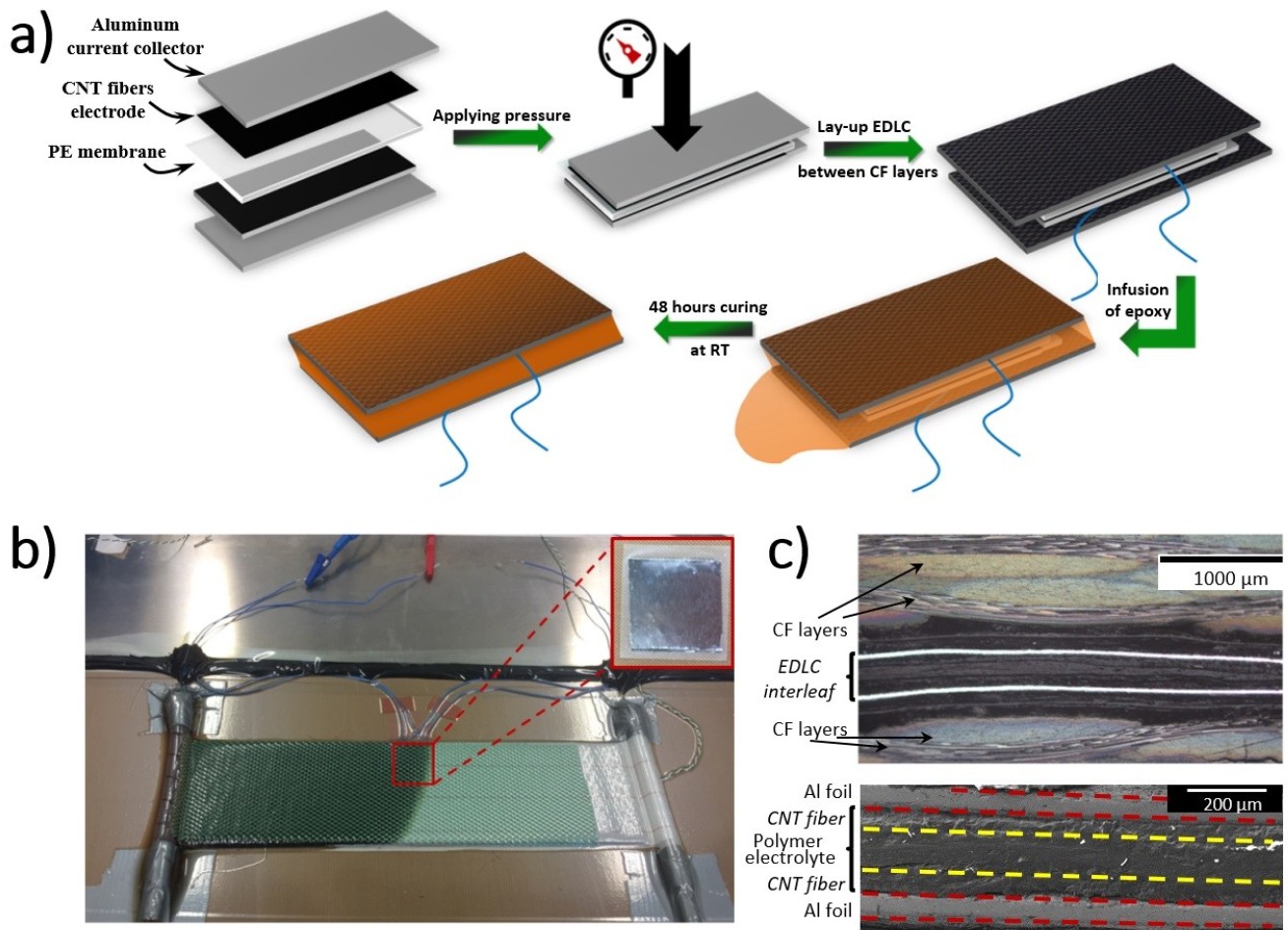

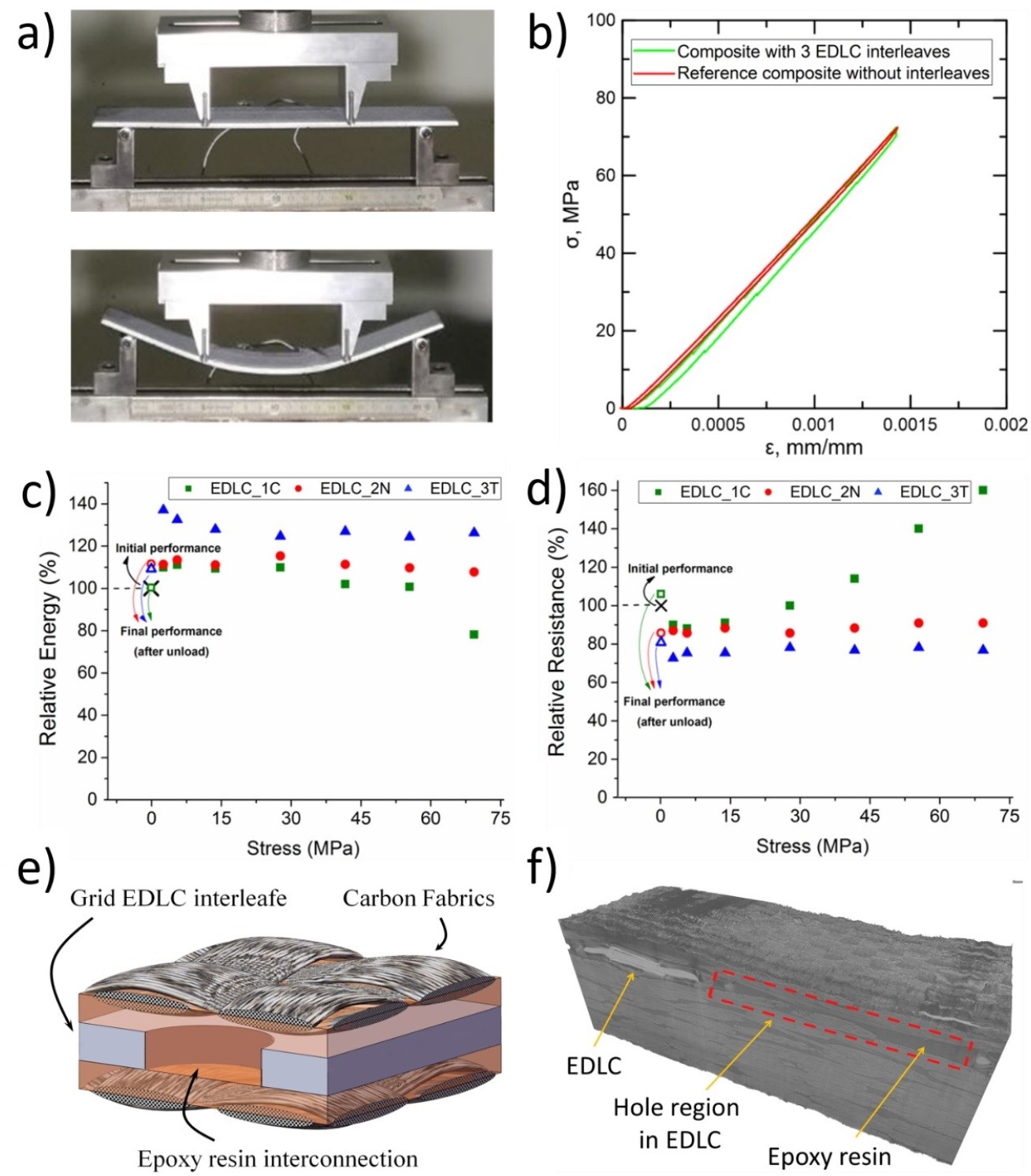

For example, structural supercapacitor composites can combine carbon fibre fabrics with thin electric double-layer capacitor based on carbon nanotube (CNT) fibre veils as interleaves, (Senokos et al., 2018) as shown in Figure 1. The first step is to produce a thin (100 micron-thick) electrochemical double-layer capacitor (EDLC) by laminating two CNT fibre electrodes with a polymer electrolyte. This material can then be integrated between structural woven CF lamina by a conventional vacuum resin infusion manufacturing process. This strategy produces structural composites with electrochemical properties that are very resilient to mechanical deformations. In-situ galvanostatic charge discharge measurements during bending show almost no changes in capacitance even at very large deformations (Figure 2 a-d). This resilience is due to the high toughness of the CNT fibre fabrics.

The second challenge is the development of a ‘structural electrolyte’ that can carry mechanical shear loads whilst providing a high ionic conductivity. Here, we use nanostructured polymer systems that organise to form bicontinuous structural and ionic-conducting phases, though thermally-induced phase segregation (Kerbs et al., 2013)) or self-assembly of block copolymers (Leijonmarck et al., 2013). For example, a fine-tuned mixture of a structural matrix with a lithium salt, segregates upon curing into a bi-continuous microstructure of stiff matrix with channels for ion transport (Shirshova et al., 2013). A more top-down approach, can exploit CNT fibre electrodes: by making macroscopic patterns in the electric double-layer capacitor part of the structural supercapacitor to promote the interconnection of carbon fibre plies by epoxy (Figure 2 e-f). This method is not only simple, but also enables the design and fabrication of composites with different balances of mechanical and electrochemical properties.

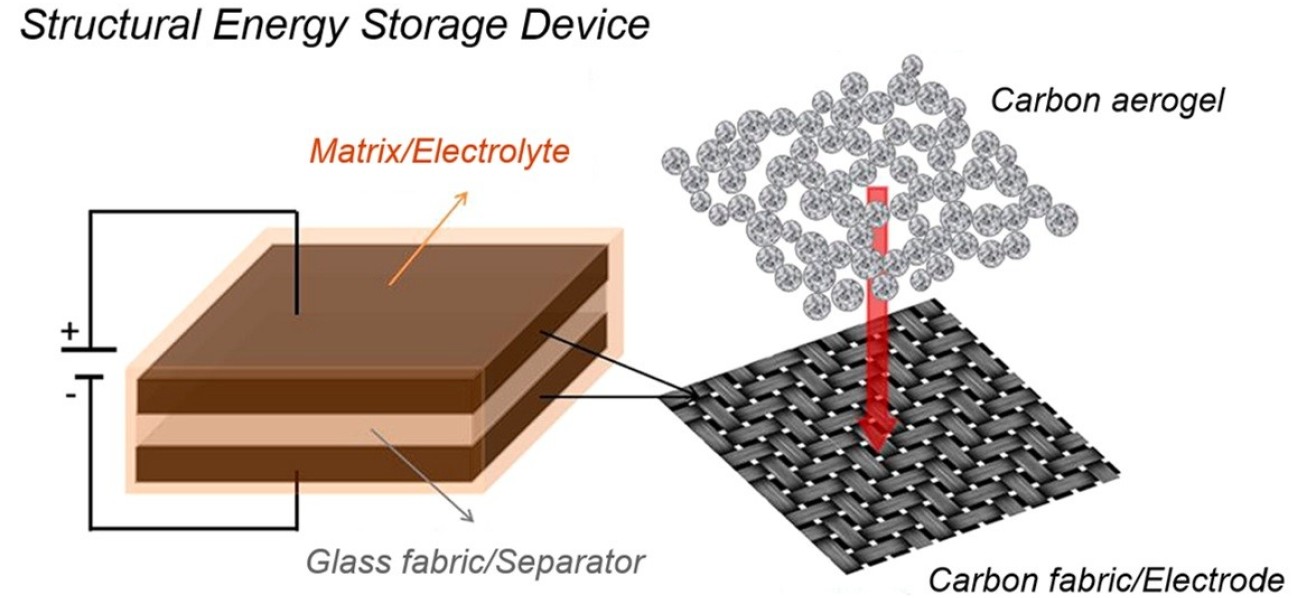

Another strategy uses high surface area carbon aerogels as a monolithic porous ‘matrix’ for conventional structural carbon fibres. The aerogel provides both electrochemical activity and mechanical rigidity (Qian et al., 2013 and Nguyen et al., 2019) schematically shown in Figure 3.

Realizing high energy/power densities and excellent mechanical properties simultaneously presents numerous challenges in terms of material properties, fabrication routes, testing, evaluation, etc. Further details are discussed in specific reviews on the topic (Asp and Greenhalgh, 2014; González et al., 2017).

References

Structural composite supercapacitors, N Shirshova, et al., Composites Part A: Applied Science and Manufacturing, Volume: 46, Pages: 96-107 (2013)

Structural carbon fibre composite/PET capacitors – Effects of dielectric separator thickness, T Carlson and LE Asp, Composites Part B: Engineering, Volume 49, Pages 16-21 (2013)

Energy storage in structural composites by introducing CNT fiber/polymer electrolyte interleaves, EA Senokos, et al., Scientific Reports, Volume: 8, Article Number: 3407 (2018)

Multifunctional structural supercapacitor composites based on carbon aerogel modified high performance carbon fiber fabric, H Qian, et al., ACS Applied Materials & Interfaces, Volume: 5, Issue: 13, Pages: 6113-6122 (2013)

Mechanical and physical performance of carbon aerogel reinforced carbon fibre hierarchical composites, SN Nguyen, et al., Composites Science and Technology, Volume: 182, Article: 107720 (2019)

Reactive and Functional Polymers, H Krebs, et al.,, Reactive and Functional Polymers, Volume: 72, Issue: 12, Pages: 931-938 (2012)

Solid polymer electrolyte-coated carbon fibres for structural and novel micro batteries, S Leijonmarck, et al., Composites Science and Technology, Volume: 89, Pages: 149-157 (2013)

Structural supercapacitor electrolytes based on bicontinuous ionic liquid–epoxy resin systems, N Shirshova, et al., Journal of Materials Chemistry A, Volume: 1, Issue: 48, Pages: 15300–15309 (2013)

Multifunctionality of Polymer Composites, Chapter 20 - Multifunctional structural battery and supercapacitor composites, LE Asp and ES Greenhalgh, Challenges and New Solutions, Pages: 619-611 (2015)

Structural composites for multifunctional applications: Current challenges and future trends, C González, et al., Progress in Materials Science, Volume: 89, Pages: 194-251 (2017)

Related links

Contact

Professor Emile S Greenhalgh

Department of Aeronautics

Imperial College London

South Kensington Campus

London SW7 2AZ

+44 (0)7958 210 089

e.greenhalgh@imperial.ac.uk