Ultrasound imaging using Full Matrix Capture (FMC) has brought a step change to the capabilities of phased arrays for the detection and characterisation of defects for Non-Destructive Evaluation (NDE). The majority of the algorithms used to process FMC data are based on the Beam-Forming (BF) approach. This has a theoretical resolution limit that has long been held as the best possible for imaging. However, recent research has shown that this theoretical resolution limit may be surpassed by extracting additional information in the data related to the interaction of waves between multiple scatterers. Such new approaches are known as Super Resolution (SR) algorithms.

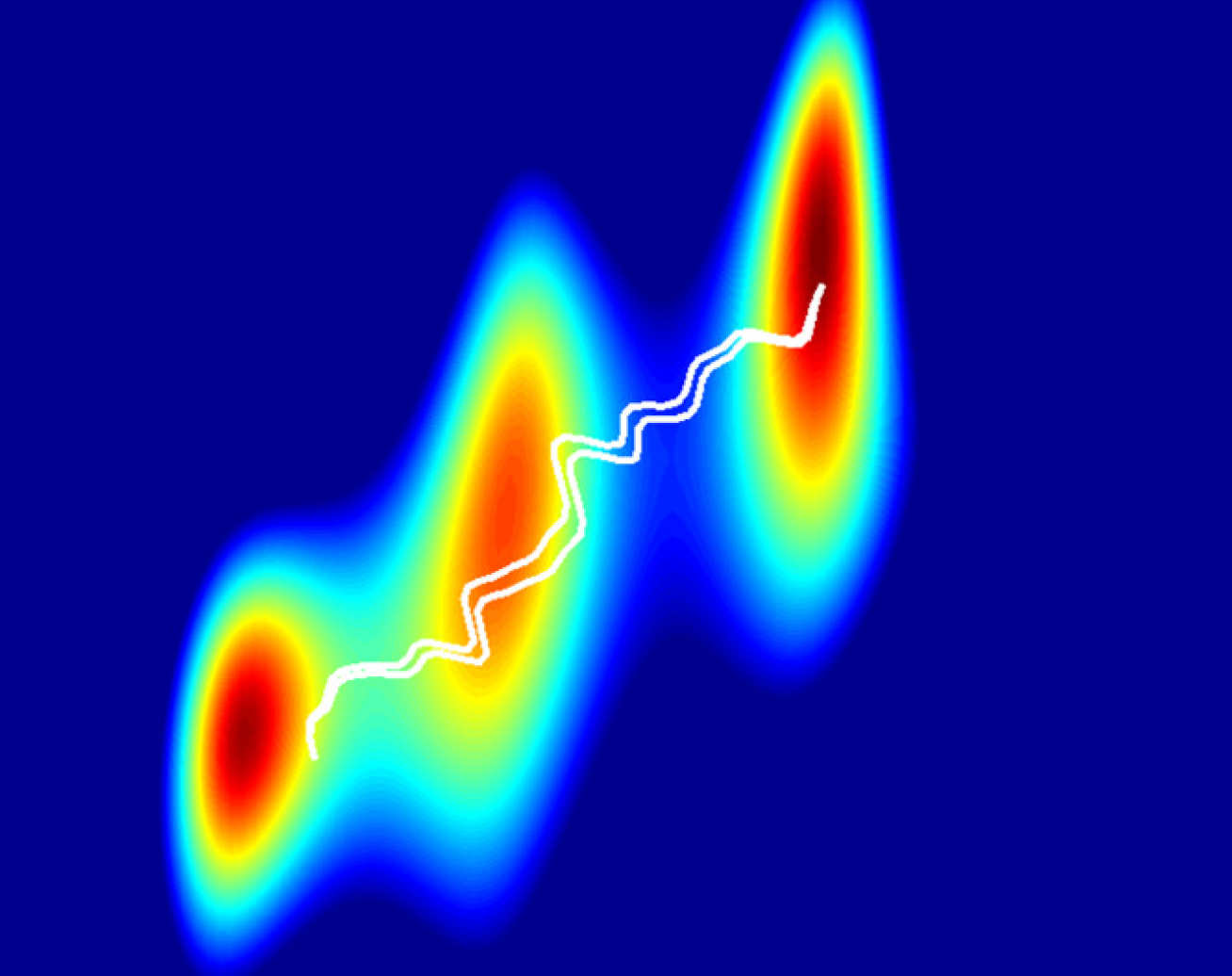

The research project, which began in 2015, has developed these SR algorithms for use in ultrasonic defect sizing of safety critical components in the nuclear industry. The application has focused on characterising small embedded defects, whose size and morphology put their accurate sizing on the edge of what is conventionally achievable within the industry currently. An example SR image of such a defect is shown below. The project has also investigated the application of these SR algorithms to the low frequency ultrasonic inspection of austenitic stainless steel welds; a type of weld which is particularly difficult to inspect.