Pham widget

- Hydrogen embrittlement of additive manufactured Inconel 718

- Designing printable alloys for additive manufacturing

- Deformation behaviour of architected meta-crystals

- Corrosion of additively manufactured Ti alloys for custom orthopaedic implants

Claudia-Tatiana Santos Maldonado (Research Postgraduate)

Claudia-Tatiana Santos Maldonado (Research Postgraduate)

Co-supervised by Roberto Morana

In collaboration with BP-ICAM

Member of Advanced Characterisation of Materials CDT

Additive manufacturing (AM), or 3D printing, has emerged as a transformative technology with significant potential in the design, supply, and fabrication of high-performance materials. Inconel 718, a nickel-based superalloy, finds applications in aerospace and energy sectors due to its exceptional mechanical properties, such as high fatigue and corrosion resistance at elevated temperatures. While the properties of conventionally manufactured Inconel 718 are extensively studied, limited knowledge exists regarding the behavior of 3D-printed Inconel 718, particularly in relation to hydrogen embrittlement—a critical concern for transportation and energy applications.

This study aims to investigate the impact of print parameters on the consolidation, solidification microstructure, and mechanical properties of Inconel 718, with a specific focus on its response to hydrogen presence. Additionally, the influence of heat treatment on hydrogen embrittlement will be explored. State-of-the-art microscopic techniques, including Electron Backscatter Diffraction (EBSD), Transmission Electron Microscopy (TEM), and Atom Probe Microscopy (APT), will be employed to unravel the underlying mechanisms governing the alloy's behavior under the influence of hydrogen.

By gaining a deeper understanding of the hydrogen embrittlement phenomena and its dependence on print parameters and heat treatment, this research will contribute to the advancement of AM processes and the optimization of Inconel 718 for enhanced performance in hydrogen-rich environments.

Raymond Wong (Research Postgraduate)

Raymond Wong (Research Postgraduate)

Co-supervised by Dr Paul Hooper

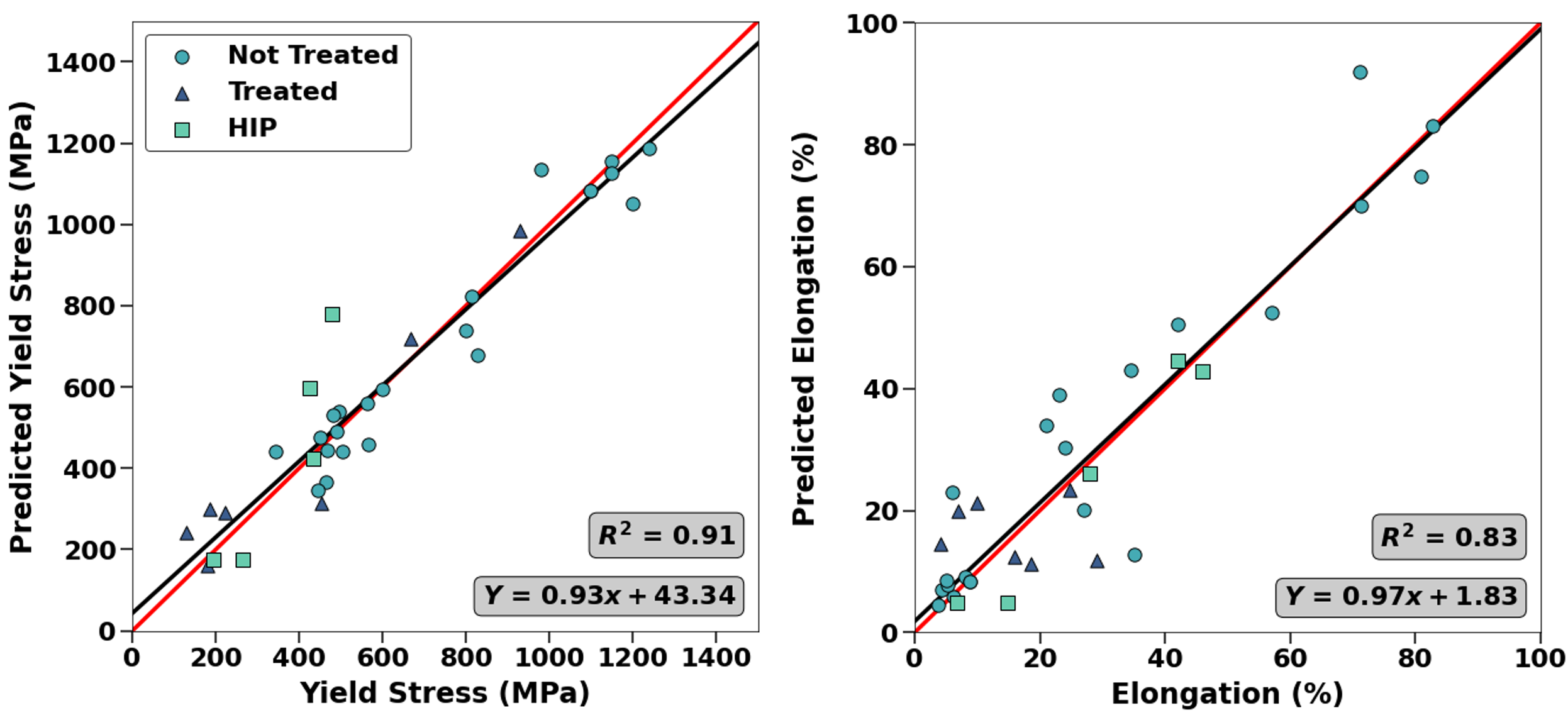

Additive manufacturing (AM) is expected to revolutionise the manufacturing industry. However, a significant challenge in AM lies in fabricating reliable and high-performance metals. One of the primary obstacles stems from the fact that the alloys currently used in AM were originally designed for other manufacturing processes and not specifically tailored for AM. As a result, the microstructures formed during AM differ significantly from those in other processes. To fully unlock the potential of AM, there is a growing need to develop new alloys specifically designed for this process. In this context, data analytics (DA) and machine learning (ML) have emerged as powerful tools capable of efficiently providing insights to the complex process for AM. This PhD research aims to use DA and ML techniques to accelerate the search and discovery of new printable alloys by establishing the links between processing and microstructure. By incorporating this knowledge into the alloy design process, it will be possible to assist the design of new alloys with desired properties and performance by controlling the process parameters, microstructure and composition.

Hsing-Lin Wu (Research Postgraduate)

Hsing-Lin Wu (Research Postgraduate)

Metallic 3D Printing revolutionizes the fabrication of intricate lattice structures previously unattainable using traditional methods. However, conventional lattice designs exhibit inadequate post-yielding properties. To overcome this limitation, a crystal-inspired design approach incorporating metallic polycrystalline structures, known as meta-crystals, has been proposed. This innovative approach enhances post-yielding properties and showcases significant potential for applications in light-weighting and improved functionality within the automotive and aerospace sectors. This PhD study focuses on a comprehensive investigation of fracture mechanisms and crack propagation behavior in crystal-inspired lattices, aiming to establish robust protocols for accurately determining fracture toughness. To achieve this, advanced techniques such as digital image correlation, X-ray computed tomography, and microstructural analysis will be employed, providing invaluable insights into deformation behavior, the influence of manufacturing defects, and the intricate characteristics of the underlying metallic base material.

Jessica Tjandra (Research Postgraduate)

Jessica Tjandra (Research Postgraduate)

Co-supervised by Dr Stella Pedrazzini, Dr Enrique Alabort and Dr Daniel Barba

In collaboration with Alloyed Ltd

Member of Advanced Characterisation of Materials CDT

Additively manufactured (AM) titanium alloys are increasingly used in biomedical applications, such as in bone replacements and joint implants. This project aims to understand the degradation mechanisms of AM titanium alloys when exposed to body fluid, under static exposure, corrosion wear and corrosion fatigue. Of particular interest is the effect of different AM lattices on the mechanical properties and material performance of these alloys. Advanced characterisation techniques such as atom probe tomography will be utilised to investigate corrosion mechanisms due to body fluid in AM Ti lattices.