Composite Mechanical Testing facilities

- Instron electropuls 10kN

- Instrumentation

- Instron 250kN hydraulic universal test machine

- Instron 100kN hydraulic universal test machine

- Instron/ceast drop tower impactor

- 250T screw driven mechanical test machine

- Instron 25kN high rate universal test machine

- Instron 50kN universal test machine

- Instron 250kN universal test machine

- In-situ microtesting

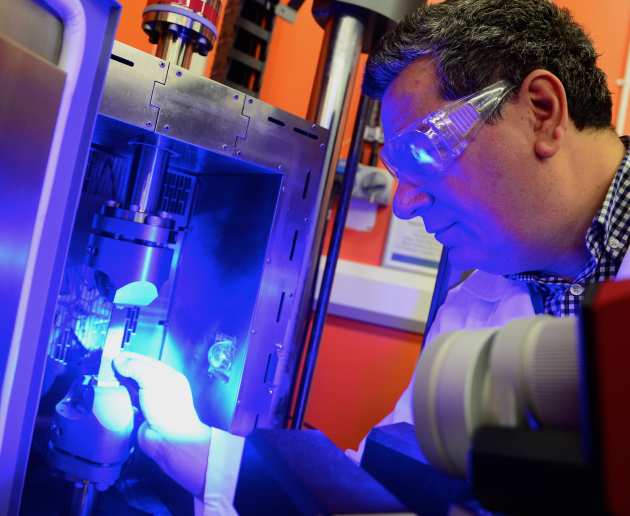

We have a 10kN linear electric motor dynamic test machine with torsion capability

We have a 10kN linear electric motor dynamic test machine with torsion capability

- Two axis linear electric motor

- Linear 10kN (7kN static) torsion 100Nm

- 60mm stroke 1.7m/s maximum velocity

- Environmental chamber capable of testing at -150 to +350°C

- Mechanical grips

- Full range of test fixtures

- WaveMatrix dynamic testing software

- 2 Analogue IN and 4 OUT channels

- 2 Instron strain channels which can be used for actuator control

- 8 Digital IN channels

- 8 Digital OUT channels

Point of Contact: Mr Joseph Meggyesi (j.meggyesi@imperial.ac.uk)

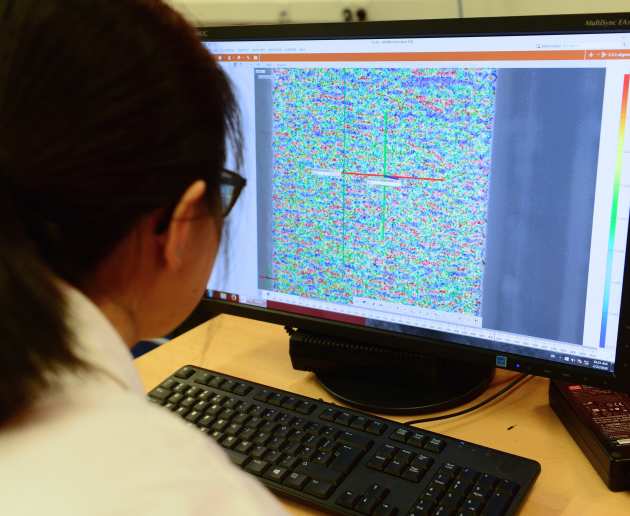

We have the following external instrumentation

We have the following external instrumentation

- Strain gauge measurement capability on all machines

- Clip on Extensometers

- Three Imetrum Optical Strain systems with a wide range of lenses

- GOM DIC (Digital Image Correlation) system

- Mistras Acoustic Emission system to locate Matrix/Fibre fractures

- Two Vision Research V12.1 High speed Cameras

- One Vision Research 25.1 camera with FAST option (million frames per second)

Point of Contact: Mr Joseph Meggyesi (j.meggyesi@imperial.ac.uk)

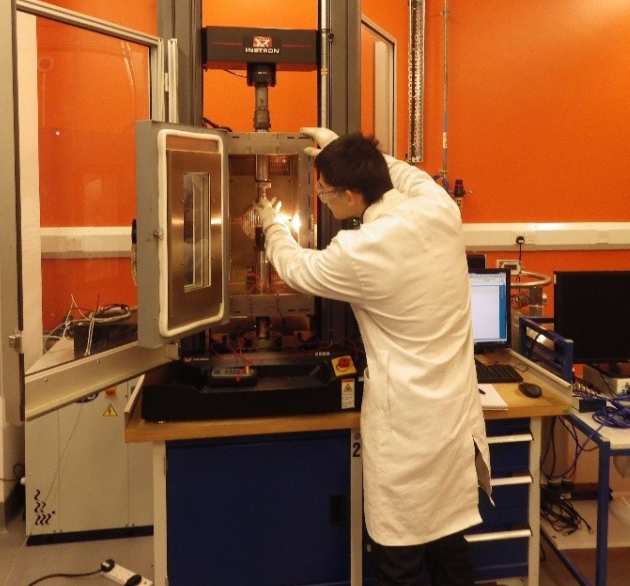

We have a 250kN hydraulic universal test machine capable of fatigue testing

We have a 250kN hydraulic universal test machine capable of fatigue testing

- Hydraulic fatigue testing machine supplied by a remote hydraulic power pack

- Dual servo valves for fast response

- 250mm stroke

- Environmental chamber capable of testing at -150 to +350°C

- Latest advanced Instron 8800 controller

- Water cooled hydraulic grips for tension/compression testing

- Instron AlignPro system fitted to ensure alignment accuracy

- WaveMatrix dynamic testing software

- 2 analogue IN and 3 OUT channels

Point of Contact: Mr Joseph Meggyesi (j.meggyesi@imperial.ac.uk)

We have a 100kN hydraulic universal test machine capable of fatigue testing

We have a 100kN hydraulic universal test machine capable of fatigue testing

- Hydraulic fatigue testing machine supplied by a remote hydraulic power pack

- 100mm stroke

- Latest advanced Instron 8800 controller

- Horizontal acting hydraulic grips capable of tension/compression testing

- WaveMatrix dynamic testing software

- 2 analogue IN and 3 OUT channels

Point of Contact: Mr Joseph Meggyesi (j.meggyesi@imperial.ac.uk)

We have a drop weight impactor for impacting composite laminates and structures. Impacts can be undertaken at temperatures. We also have the unique capability to impact components whilst under compressive loading.

We have a drop weight impactor for impacting composite laminates and structures. Impacts can be undertaken at temperatures. We also have the unique capability to impact components whilst under compressive loading.

- Fully automated drop tower including anti-rebound device

- Maximum potential energy 1800J

- Maximum mass 70kg

- Maximum velocity 24m/s with low mass carriage

- Environment chamber -70°C to 150°C

- Maximum impact force 90kN

- 14 bit 2Mhz data sampling

- Bespoke compression frame for panels up to 1.2m long x 1m wide with up to 150kN compression capability

- The bespoke frame has recirculating ball X Y slideways to easily position the impact at the required location. Extra Z height is adjusted by spacers.

Point of Contact: Mr Joseph Meggyesi (j.meggyesi@imperial.ac.uk)

We have a hyper stiff compression test machine, particularly designed for testing of stiffened panels and large composite structures. The high stiffness of the machine ensures that there is negligble recoil during failure of the test component, hence minimising the degree of post-failure damage.

We have a hyper stiff compression test machine, particularly designed for testing of stiffened panels and large composite structures. The high stiffness of the machine ensures that there is negligble recoil during failure of the test component, hence minimising the degree of post-failure damage.

- Loading 2500kN

- Panel size 1.5m long by 1.2m wide

- Data logger to collect load/displacement/strain

- 2mm min maximum test speed

Point of Contact: Mr Joseph Meggyesi (j.meggyesi@imperial.ac.uk)

We have a 25kN hydraulic universal test machine capable of single shot or fatigue testing.

We have a 25kN hydraulic universal test machine capable of single shot or fatigue testing.

- Hydraulic 4 servo valve high rate/fatigue testing supplied by a remote hydraulic power pack

- 3m/s max velocity, 250mm stroke

- 3 Servo valves can be selectively isolated for precision control for low amplitude fatigue testing

- Latest advanced Instron 8800 controller

- Hydraulic grips capable of tension/compression testing

- WaveMatrix dynamic testing software

- 2 analogue IN and 3 OUT channels

Point of Contact: Mr Joseph Meggyesi (j.meggyesi@imperial.ac.uk)

We have two 50kN universal test machines with a full range of fixtures to test standards

We have two 50kN universal test machines with a full range of fixtures to test standards

- Maximum capacity 50kN with a range of load cells down to 10N;

- Full range of test fixtures and a fully equipped workshop with CNC machining capability to modify or manufacture bespoke fixtures;

- Full range of instrumentation;

- Pneumatic yarn grips;

- Environmental chamber capable of testing at -150 to +350°C;

- BlueHill software with Profiler option;

- 6 analogue IN and 4 analogue OUT channels;

Point of Contact:Mr Joseph Meggyesi (j.meggyesi@imperial.ac.uk)

We have a 250kN universal test machine with hydraulic grips

We have a 250kN universal test machine with hydraulic grips

- Maximum capacity 250kN with a range of load cells down to 10N;

- Full range of test fixtures and a fully equipped workshop with CNC machining capabilityto modify or manufacture bespoke fixtures;

- Full range of instrumentation;

- Pneumatic yarn grips;

- Hydraulic grips for tension/compression testing;

- Environmental chamber capable of testing at -150 to +350°C;

- BlueHill software with Profiler option;

- 10 analogue IN and 4 analogue OUT channels;

Point of Contact: Mr Joseph Meggyesi (j.meggyesi@imperial.ac.uk)

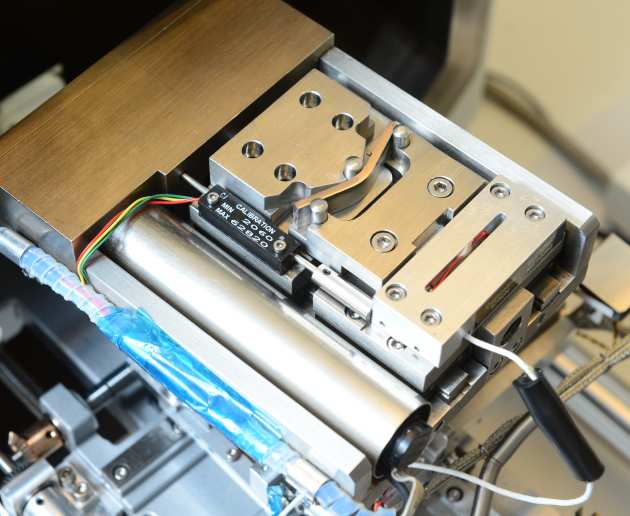

We have a microtester for undertaking in-situ testing of composites

We have a microtester for undertaking in-situ testing of composites

- Load capacity 4kN

- Maximum stroke

- Maximum displacement

Point of Contact: Dr Frank Gommer (f.gommer@imperial.ac.uk)

Contact us

The Composites Centre

Imperial College London

South Kensington Campus

London

SW7 2AZ

United Kingdom

Email: ae.composites@imperial.ac.uk